Customer challenge

- Need to do design efficiently, reduce errors, and generate full and accurate production information

- Need to constantly improve and develop

Basic design of double-ended Ro-Pax ferry

Customer challenge

Cadmatic solution

“The creation of shell plating and production documents in Cadmatic is a great help. Normally, this is a very tedious and time-consuming job that we currently cannot imagine doing without Cadmatic.” – Michał Strabel, Midcon Chief Executive Officer

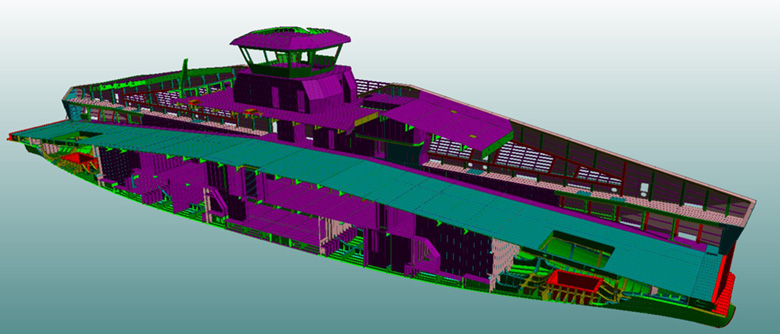

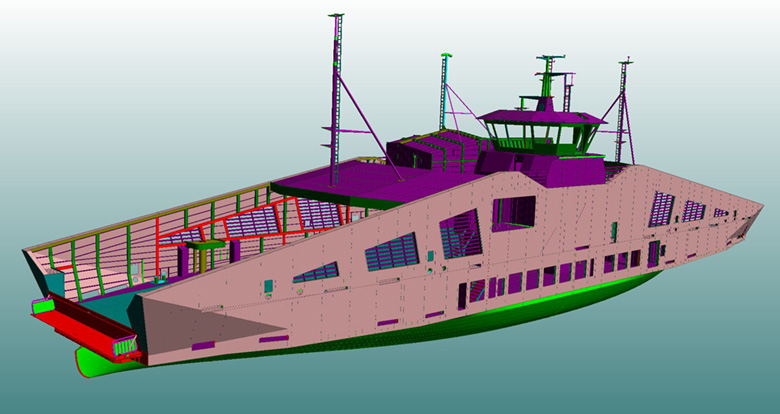

In August 2021, Norwegian operator Norled took delivery of the “hydrogen-ready” Hydra, a double-ended Ro-Pax ferry and one of the first passenger vessels designed with capabilities for liquid hydrogen propulsion. The basic design of the vessel was developed together by LMG Marin and Midcon Designer Ltd (Midcon) from Poland with Cadmatic software.

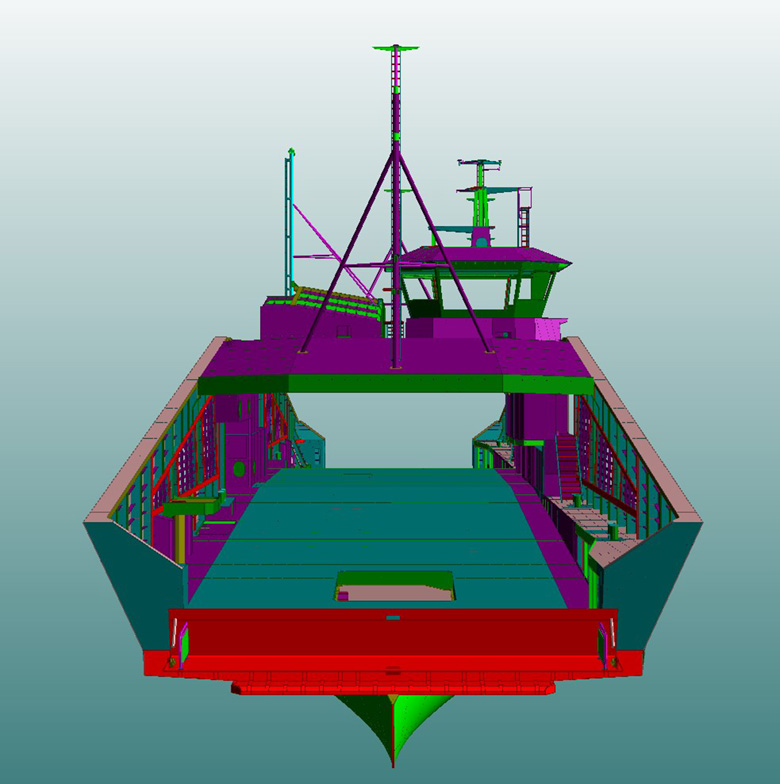

The vessel stands out for various reasons, among those its highly distinguished shape, sloping main deck, passenger section under the main deck, several interdecks on different planes, and the partial roof above the deck. The vessel is 82.4 meters long and can carry up to 292 passengers and 80 cars.

Midcon Chief Executive Officer Michał Strabel says that it gave his design team a lot of joy to combine everything on the Hydra project into a coherent whole.

“This project really allowed us to showcase our skills and experience. The inconspicuous pocket for the MOB boat, which is covered with a shutter on the side, turned out to be quite a challenge, but we love challenges. To provide enough space and integrate the pocket into the structure of the ship, we had to generate several ideas and make many modifications before we achieved the desired effect,” says Michał.

For the time being, Hydra is operating on battery power, but can switch to run solely on LH2 once fuel availability is secured. The hydrogen tank was placed on the open deck, which Michał says was nothing new for his team.

Some interesting novelties in the design, however, include the protective wall between the tank and the wheelhouse, the rooms for servicing the hydrogen system, as well as the vessel’s gas mast. Michał indicates that this was important to prevent gas accumulation and accommodate the very low system operating temperature of -196 °.

Midcon is an experienced Cadmatic user and started its first projects with the software already in 2005. It specializes in seagoing vessels, but has also completed projects such as shuttle boats, tugs, icebreakers, passenger ships, bulk carriers, container ships, coast guard units, barges, drilling ships, and FPSOs. Cadmatic is used for the basic and detail design of the vessels.

“For detail design, we use both CADMATIC Hull and Outfitting and generate full production documentation. For basic design, we usually only use CADMATIC Hull, but sometimes we receive a 3D model for a device or system that we import with CADMATIC Outfitting. In more complex projects, this speeds up the work a lot and guarantees a well-designed project.”

Michał says that Midcon models the entire structure of ships during basic design, and sometime the shell plating too.

“This allows us to obtain a consistent model from which to generate documentation and two important pieces of information: the weight of the fuselage with the center of gravity, and the material list for our clients.”

According to Michał, a well-designed 3D model ensures that the generated cross-sections are consistent and significantly reduces the number of errors compared to documentation prepared manually in 2D.

“The creation of shell plating and production documents in Cadmatic is a great help. Normally this is a very tedious and time-consuming job that we currently cannot imagine doing without Cadmatic,” Michał adds.

CADMATIC eBrowser is also used often at Midcon to share the model with colleagues for discussion and planning.

“eBrowser makes our work much easier and faster. It is a fantastic tool that gives you the ability to view any problem or collision from all sides. It greatly facilitates communication and ensures that we are discussing the same thing.”

Michał concludes by saying that Midcon is increasingly delving into Cadmatic to discover new opportunities and ways of making their work even more efficient.

“I think that Cadmatic can offer us a lot and facilitate our work. I am also happy that the software is constantly evolving to make our work easier.”

Read more about Cadmatic ship design solutions.