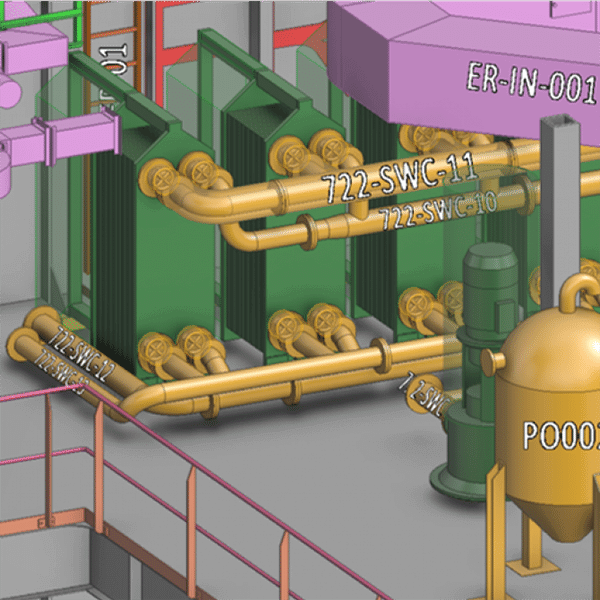

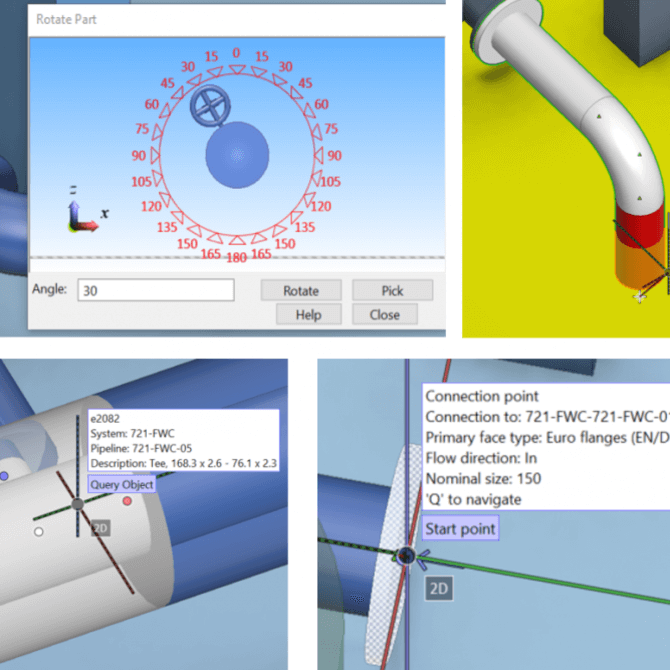

Complete detailed 3D: piping, outfitting, HVAC and cables

CADMATIC Outfitting Detailed Design consists of efficient modules that help your design team to create complete and accurate 3D outfitting models. The core system for outfitting design is 3D Outfitting and Piping Design, but it also includes electrical design, air duct spools and HVAC, piping supports, steel outfitting, and weld management. We also have various interfaces for special software packages, such as stress analysis or import-export of 3D and 2D interfaces.

The advanced 3D viewing techniques and model database structure keep the design model extremely light and user friendly, even in the biggest and most complicated vessels or offshore models. The complete integration with CADMATIC Hull ensures that both hull and outfitting designers work in the same environment and can directly solve mutual questions, such as penetrations.

Specification-driven modeling of pipes and cable trays ensures that the correct materials, sizes, and components are used during modeling. We support work processes with globally distributed teams and ensure IPR safety, allow the sharing of 3D models with eBrowser and on tablets with eGo and the direct use of the results of the design phase in the eShare information management portal.

Watch Outfitting demo online