Customer challenge

- Need to use best-in-class software for different design disciplines with seamless integration.

Integrated 3D design combines the best of both worlds

Customer challenge

Cadmatic solution

“It enables detailed design to facilitate production design and modeling and combines these two design phases on one platform. Moreover, it avoids mistakes when updating or transferring drawings.” – Li Lu, Vice-President

Established in 1964, the Shanghai Merchant Ship Design and Research Institute (SDARI) is one of the largest ship research and design companies in China. The affiliate of the China State Shipbuilding Corporation Limited has developed more than 1,200 different vessels. It has used Cadmatic software since 2008 for piping design, diagrams, hull design, and communication and has more recently implemented the CADMATIC eShare information management solution.

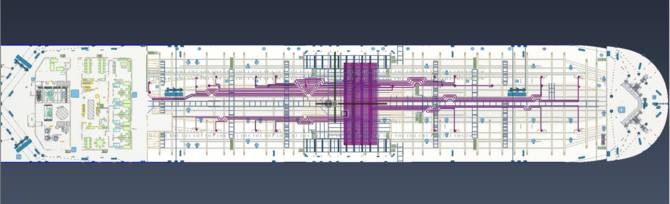

To date, the institute has done the detail design of a 49000 DWT chemical tanker, 2750 TEU container vessel, 120000 DWT bulk carrier, 2500TEU container vessel, 85000 DWT bulk carrier, 23000 TEU container vessel, and a 65000 DWT semi-submersible ship with Cadmatic. It has also implemented the software in some offshore projects.

SDARI are planning to expand their scope of Cadmatic use.

“In the future, we will use Cadmatic as an important platform for full 3D design implementations and promote the software for all design projects including transportation ships, offshore engineering ships, and cruise liners,” says Li Lu, SDARI Vice-President.

SDARI Vice-President Li Lu has been impressed with how Cadmatic diagrams drive 3D modelling.

SDARI has implemented an integrated approach to 3D design where different software packages are applied. In practice, this is realized via collaboration between different design disciplines based on a single data source. In SDARI’s view, different disciplines have divergent requirements and focus areas for software, while the different software packages also have their own strengths.

“Therefore, our strategy is to have the best of both worlds. We combine multiple software packages to realize integrated design. NAPA is powerful in ship general design as well as calculations, while Cadmatic's strengths are piping design, 3D layout, and diagrams. With the help of establishing a complete set of design standards, we can integrate models from different software packages,” Li Lu explains.

Cadmatic 3D model of a 23000 TEU container vessel designed by SDARI.

Over the years, SDARI has worked closely with Cadmatic support staff to customize the software to suit SDARI’s design modes and habits. These developments have helped to align the institute’s standards and 3D design and has further increased the efficiency of 3D design.

“We believe that after accumulating more experience, improving skills and developing better tools, a complete transition to Cadmatic 3D design will bring SDARI more benefits,” Li Lu adds.

The close collaborative relationship between SDARI and Cadmatic continues and is currently focused on implementing the software in production.

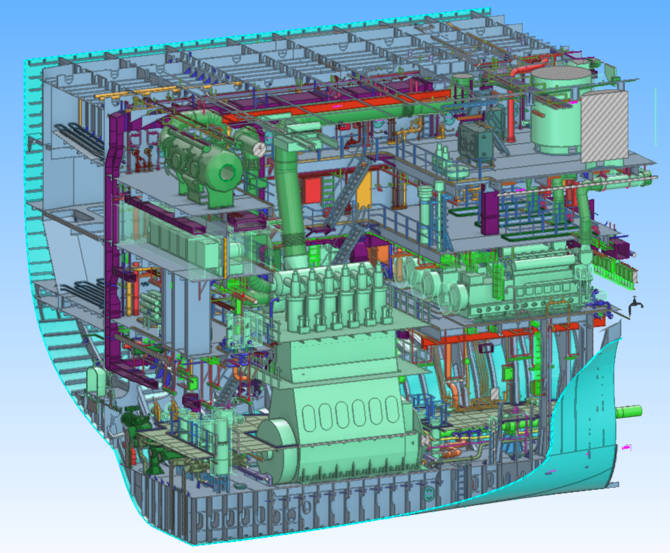

SDARI has already used Cadmatic for the production design of the engine room area of a 49000 DWT chemical tanker and the mid-body area of an 85000 DWT bulk carrier. Much collaborative work has been done behind the scenes to meet challenges and to ensure that the production standards of Chinese shipyards are met. This has been successfully achieved for areas such as hull modeling, design coding, nesting, and profile production, while outer plate expansion, secondary line drawing, and symmetrical modeling still require development.

Cadmatic 3D model of the engine room area of a 49000 DWT chemical tanker.

According to Li Lu, SDARI is collaborating with Cadmatic to meet challenges related to standards for air ducts, structural background drawings and to improve the standard configuration of CADMATIC Hull and Outfitting.

“After solving these remaining challenges, we plan to select suitable projects to implement Cadmatic software more comprehensively for production design,” says Li Lu.

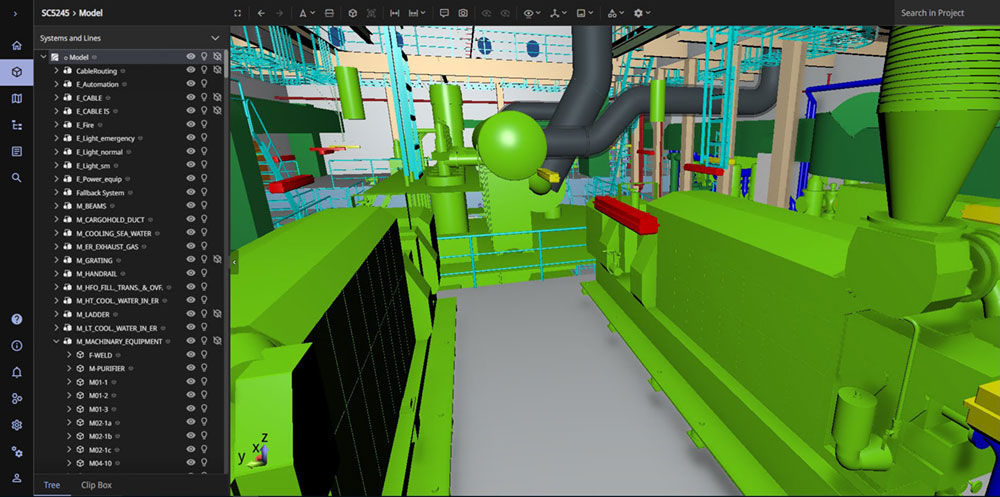

Li Lu has been impressed with the powerful way Cadmatic diagrams drive 3D modeling.

“It enables detailed design to facilitate production design and modeling and combines these two design phases on one platform. Moreover, it avoids mistakes when updating or transferring drawings,” Li Lu explains.

3D model image of a 49000 DWT chemical tanker designed by SDARI with Cadmatic.

The CADMATIC eBrowser project review tool has been in use for several years at SDARI. It is used to compress models into a single document, after which SDARI employees take it with them to customer meetings.

According to Senior Engineer Shi Guangwei, CADMATIC eShare is used at SDARI to integrate 3D design models with project management systems, which allows for a better presentation of 3D model outcomes to management personnel. This provides an intuitive understanding of the progress of 3D design.

He indicates that eShare has also been useful in associating 2D drawings with 3D models, thereby facilitating better collaborative design among various specialties and achieving a 2D-3D linkage. External drawings and documents have also been integrated in eShare, thereby centralizing project data and enabling online viewing.

"We are currently researching the use of the eShare platform to publish design results to clients, and utilizing the markup functionality for model-based design reviews," says Shi Guangwei.

Watch a video of SDARI use of CADMATIC eShare below.

Read more about Cadmatic ship design solutions.