Customer challenge

- 3D model files of vessels longer than 10 metres are too large and require extremely powerful workstations.

- Desire to increase efficiency and gain competitive advantage.

Yacht design with Cadmatic

Customer challenge

Cadmatic solution

"The extensive customization options in system administration are also very advantageous. This assists us to provide custom components, listings and drawings as requested by our customers." – Sergio Allegria, Owner

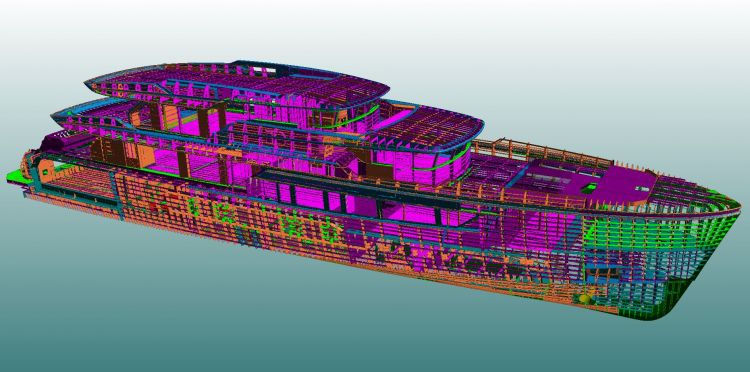

Kyma (formerly 3J Yachting) has a long history of Cadmatic use. The Italian engineering and consulting company from Follonica acquired CADMATIC Hull in 2010, after carefully evaluating different software packages. From 2013 onwards, Kyma also started using CADMATIC Outfitting. Kyma chose Cadmatic due to the fully customizable parametric solutions for both 3D modeling and production documents.'

Kyma’s core business is nesting and piping production documentation for the Italian yacht building industry. The company also offers basic and detailed design and consultancy during all steps of construction for shipyards and subcontractors worldwide.

“It is quite easy to start modeling and drawing models with Cadmatic. A basic user can learn Hull and Outfitting in no more than two weeks. The administration training was important because you need experienced Cadmatic administrators to get the most out of the software,” says Sergio Allegria, owner at Kyma.

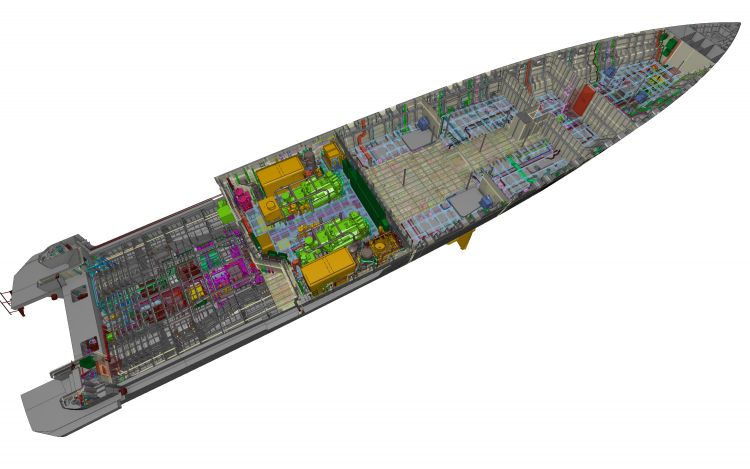

Before adopting Cadmatic software, Kyma used nesting and piping tools from other CAD software providers. They encountered difficulties to manage 3D models and make the necessary production drawings in projects with ships and yachts in excess of than 10 meters. The resultant files were too large, which in turn required extremely powerful workstations.

“With Cadmatic this is not a problem for us anymore. The Cadmatic models are light and the software can be used with a regular workstation. We can easily make production drawings for big yachts, which is very important for us,” says Sergio.

Kyma reports superior production drawing results with Cadmatic .

“I can confirm that Cadmatic really helps us to be faster and more accurate than other companies, especially for the shipyard / classification society we work with. The extensive customization options in system administration are also very advantageous. This assists us to provide custom components, listings and drawings as requested by our customers,” says Sergio.

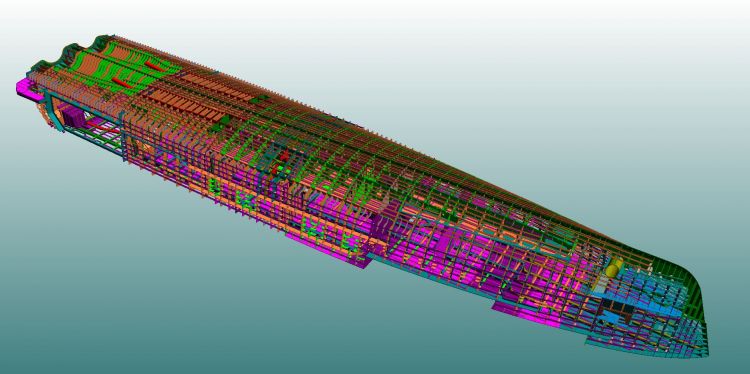

The new version of CADMATIC Shell Plate Development in use at Kyma has made defining shell plates much easier. It calculates shell plates extremely accurately and also calculates templates for bending, including marking lines. It generates elongation lists, 2D sketches and the geometry of each shell plate ready for nesting.

According to Sergio, the shape of a modern yacht cannot be defined with only plane plates, since it is too elaborate. In this respect, he indicates that Cadmatic has a big advantage:

“We can now see the actual shape and thickness of the shells in the hull viewer. The shell plates can also be exported to our customers as solids in other formats”.

One of Kyma most recent projects was a 44-meter alloy yacht for San Lorenzo Shipyard. The diagrams were designed and the technical layout was defined first, after which the structural blocks were completed and the last drawings for piping were finished, all with Cadmatic software.

“When we design series like the 44 meter alloy yacht, several yachts are similar, but never identical. Cadmatic offers an excellent solution for this, because the settings, norms and specifications of the parent model can be copied easily to a new project. The new model is, nevertheless, independent from the parent model and can be set up in any way,” Sergio explains.

As the yacht was a prototype, some modifications and changes needed to be done on the Hull side in a very short period. Kyma used the powerful parametric possibilities of Cadmatic effectively in order to meet the tight schedule.

“In a short amount of time we can make changes in CADMATC Hull, whilst in Outfitting we can easily work on two different projects in parallel, the first and second yacht of the 44 meters series, by just copying 3D routing and drawing layouts using .mdl and .cx files.”

The second yacht of the series and the planned third one will also be done in Cadmatic . Other current projects include a 75-meter steel/alloy yacht for NCA shipyard, where Kyma gis doing scantling and nesting, but no outfitting, as well as the hull blocks for a 107-meter yacht for Benetti.

Kyma is satisfied with Cadmatic support including new and improved functionalities and bug fixes that are brought out every tertiary.

“For us it is really important that we do not have to wait for a long time for software updates. The improved functionality for faster collision control and the new functionality for inspection views are some examples of additions we appreciate very much. The support has always been efficient and fast in answering our questions”.

Kyma generally uses the CADMATIC eBrowser for communication with clients in all project phases. This applies to design, meetings at the shipyard, and onboard visits. Recently, they have also tested CADMATIC eShare.

“We were very impressed with eShare’s capabilities. The model and document publishing is very useful, but what really stands out for me is the loading and linking of other documents not prepared for eShare integration, or those from different sources. These tools are very powerful and helpful, especially for managing the relationships with our clients and for cooperating with shipyards”.

Kym is currently considering adopting eShare for internal management.

Read how your design and engineering company can gain a competitive advantage with Cadmatic ship design solutions.