Customer challenge

- Integrate all disciplines within basic design and not leave it for detail design and production stages.

- Need to improve access to design data and facilitate class approval

Taking 3D ship modeling to a new level

Customer challenge

CADAMATIC solution

"Even though structural 2D plans may be good, the 3D model takes your design to the next level. It allows us to set priorities and take control of the design process from the very beginning." – Andrey Zherebetsky, Director

C-Job Nikolayev is a part of the independent ship design company C-Job Naval Architects. Its first international office was opened in Nikolayev, Ukraine in September 2017. The naval architecture company focuses mainly on 3D basic design modeling and full-scope detail engineering. Cadmatic has been an integral part of the company’s toolset in taking its basic design to a new level.

According to C-Job Nikolayev Director Andrey Zherebetsky, the global order book for cruise vessels, superyachts and special vessels has grown steadily this year. He also points to a report by international classification society RINA Services that indicates a trend towards larger vessels and more high-tech engineering. Some more traditional trends include the minimizing of building costs and reduction of lead times.

Andrey indicates that the integration of all disciplines within basic design is one of the biggest challenges faced by naval architects.

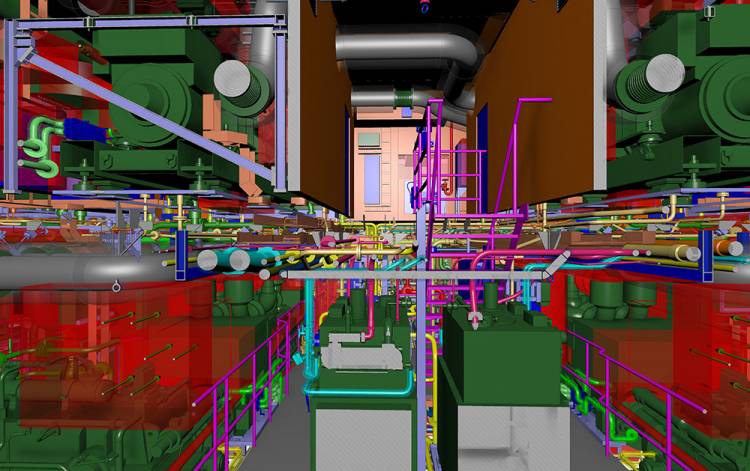

“Unfortunately, it became normal practice in our industry to produce visually attractive and approved basic designs, while shifting all the integration challenges to the detail design and production stages. Here I mean HVAC, cable trays, exhaust, ER and machinery space arrangements, and principal routing. What is very convenient for design companies, turns out to a big problem at shipyards with massive additional costs for the production phase.”

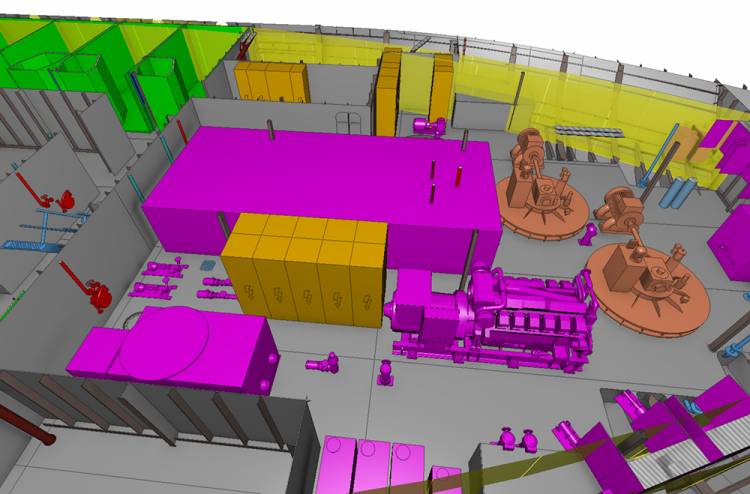

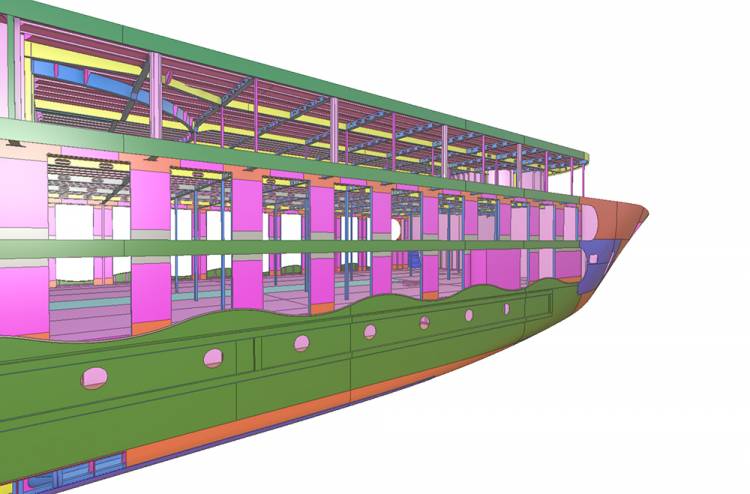

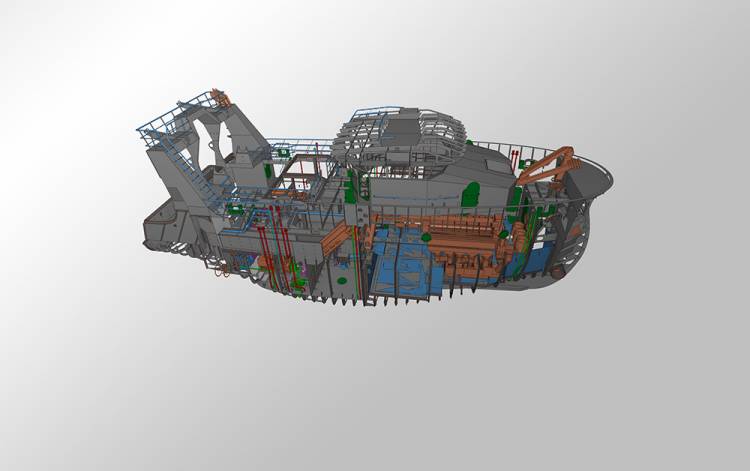

In order to avoid the afore-mentioned problems, C-Job Nikolayev employs a novel approach of creating both basic and functional design. The approach, which has become the standard way of working at C-Job Nikolayev, uses and relies on principle solutions designed by C-Job Naval Architects and further development during the 3D modeling processes with Cadmatic by the C-Job Nikolayev team. Thanks to this approach, C-Job Nikolayev’s engineers can provide fast and reliable design solutions for mega yachts, cruise ships, dredgers and offshore vessels.

“It is fast and easy to create a Cadmatic model from scratch and to create arrangement, structural and layout drawings and generate sketches. Due to the unique and optimized procedures, C-Job Nikolayev can respond quickly to changes and modifications with the CADMATIC Hull and Outfitting modules. Combined with the drafting functionality, we develop basic designs, take care of the details and further production activities,” says Andrey.

Typically, C-Job Nikolayev starts modeling simplified panels of major structural elements in CADMATIC Hull. The model highlights areas that require additional attention.

Even though structural 2D plans may be good, the 3D model takes your design to the next level. It allows us to set priorities and take control of the design process from the very beginning. Any issues that may arise can be solved and excluded during early basic 3D design. If you use only a 2D approach, such issues may only pop up during detail design, or even worse, during production. This in turn influences resources, materials and planning,” Andrey explains.

C-Job Naval Architects uses Cadmatic models to provide their clients with real-time updates on steel and equipment weight estimations as well as material take-offs that can be used by the shipyard for placing precise material preorders much earlier.

All major equipment, pipelines, HVAC and cable trays require space reservation. At C-Job Nikolayev, these elements are part of the model already at the basic design stage. This allows the designers to do their work while also taking other disciplines into consideration. Areas that require additional attention are identified and registered in the system. C-Job Nikolayev delivers basic and functional design to the client that is ready for the next stage: detail design.

“Working with laser-scanned data is fast, easy and efficient.”

C-Job Naval Architects also makes use of Cadmatic’s distributed design system that allows design teams to collaborate and work simultaneously on the same projects.

"With Cadmatic’s 3D model and master-replica solution, our teams are linked in the main project environment from the start. Different teams and subcontractors may be working on different areas they’re responsible for, but thanks to the software they always work with the most up-to-date model.

In addition to efficiency gains during basic design, C-Job Nikolayev appreciates how Cadmatic improves access to design data and facilitates class approval.

“There is no need to wait for the next revision of specific arrangement drawings anymore. The design data is available in real time. This allows our engineering team to control all critical areas via markups during the full design process,” says Andrey.

He indicates that the CADMATIC eBrowser model facilitates class review and approval, which means that there is no need to produce 2D drawings first.

The number of engineering projects with laser-scanned data as inputs has significantly increased in the C-Job Nikolayev portfolio over recent times. Andrey says that C-Job Nikolayev has successfully delivered more than 20 “point cloud designs” from 2018 to 2019.

“With Cadmatic solutions, working with laser-scanned data is fast, easy and efficient nowadays. The opportunity to examine an existing ship model with a laser scanner is advantageous compared to traditional ways of handling such projects. To sketch a new model, we need to refer to existing equipment placement in order to avoid equipment collisions. The point clouds give us a starting point with gaps we need to fill.”

Andrey explains that the use of point clouds does not only improve efficiency during surveys of client facilities but also increases the accuracy of the final 3D model.

“At C-Job Nikolayev we use point clouds not only for retrofit projects but also for newbuild designs. It is a challenge to design a new vessel with laser-scanned data from the client that provides an obligatory layout for machinery solutions. No ship is the same, but it is a good idea to use the client’s best and known practices. While developing documentation, we need to manage changes fast and effectively. Point cloud implementation ensures project accuracy based on an existing ship model and that there are no unfortunate surprises during installation.”

C-Job Naval Architects is a leading ship design and engineering company with offices in the Netherlands, Ukraine, and the USA. The company has impressive design capacity provided by over 150 in-house naval architects and marine engineers. C-Job Nikolayev LLC is a C-Job Naval Architects company that is the preferred partner for a wide range of shipyards and design offices. The C-Job Nikolayev team includes 50 engineers of different specializations; skilled, experienced, flexible and mobile.

Read how your design company can benefit from Cadmatic ship design solutions.

Basic design of double-ended Ro-Pax ferry

Multi-disciplinary quality

The engineering and design company Sea Master is based in El Puerto de Santa María in the south of Spain.