Customer challenge

- Maintain seamless collaboration among multiple stakeholders across different locations.

- Manage and iterate on prototype designs.

- Facilitate efficient collaboration between design team and factory floor.

Customer challenge

Cadmatic solution

“The use of a single ship model for all stakeholders has enabled real-time updates and changes, drastically enhancing collaboration efficiency, as observed in our operations.” – Mr. Segismundo “Jun” Exaltacion, Jr. (President) at TTSP

Tsuneishi Technical Services (Phils.) Inc. (TTSP) is a pivotal design center for the Tsuneishi Group, supporting three shipyards across Japan, China, and the Philippines. In addition to its mother company, TTSP also provides services to external EPCM and other shipbuilding companies. The use of Cadmatic software has assisted TTSP to make gains in collaboration, efficiency, and precision in ship design and manufacturing.

TTSP’s services include ship detailed design, retrofitting & reverse engineering, 3D scanning, and 3D modeling & library catalogue making.

TTSP uses an in-house app developed by Mr. Paolo dela Cruz (Hull Sr. Design Engr.) to streamline Cadmatic workflows.

One of the most significant challenges in shipbuilding is maintaining seamless collaboration among multiple stakeholders, often spread across different geographical locations.

According to Mr. Segismundo “Jun” Exaltacion, Jr. (President) at TTSP, Cadmatic is a good solution, which significantly expedited notifications and alerts compared to other software used previously.

“The use of a single ship model for all stakeholders has enabled real-time updates and changes, drastically enhancing collaboration efficiency, as observed in our operations,” Pres. Jun says.

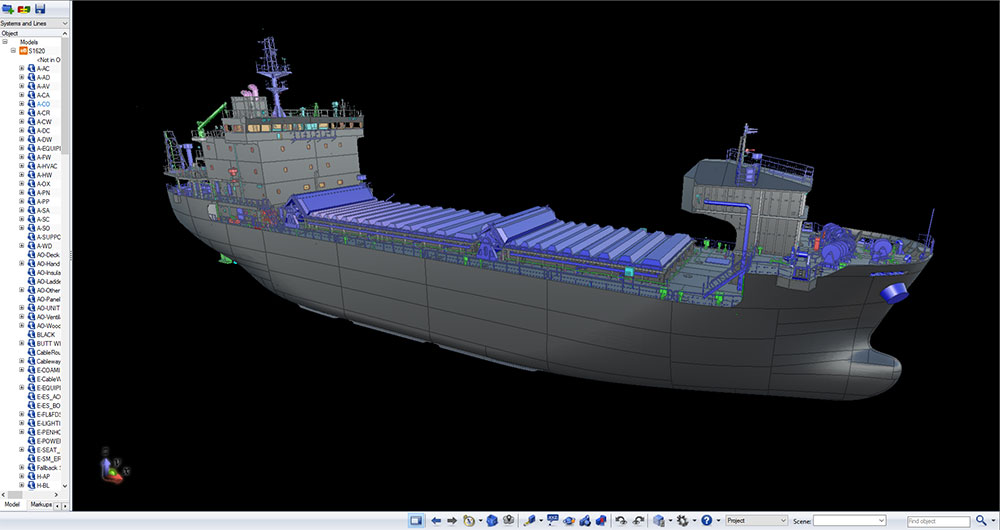

Self-unloader Limestone Carrier with Hybrid Propulsion with LNG engine and batteries. Modelled in Cadmatic.

The journey of managing and iterating on prototype designs has been facilitated for TTSP through Cadmatic's Hull Cos version and sistership management features. These tools have been valuable in ensuring the consistent application of Tsuneishi’s rigorous design standards across all sister and series vessels, originating from their prototypes. This has not only streamlined the design process but also upheld the quality and integrity of each vessel produced.

General benefits that can be gained from efficient sistership management include:

TTSP also highlights Cadmatic’s role in streamlining their output generation process.

“Utilizing customizable tools such as ICGD, Excel templates, and labels, Cadmatic software allows us to create precise output customization and automation. The software's intuitive interface and integration with external tools facilitate an efficient and consistent design process, aligning outputs meticulously with our established design standards, Mr. Glenn Sobrio (Cad Admin. Supervisor) explains.

Mr. Paolo dela Cruz (Hull Sr. Design Engr.) points out that Cadmatic's integration with TTSP's in-house applications has significantly improved efficiency in material procurement.

“With Cadmatic we can generate detailed data files for pipe spool information and hull parts, which facilitates seamless information transfer to procurement teams, thereby enhancing accuracy and reducing lead times in the procurement process.”

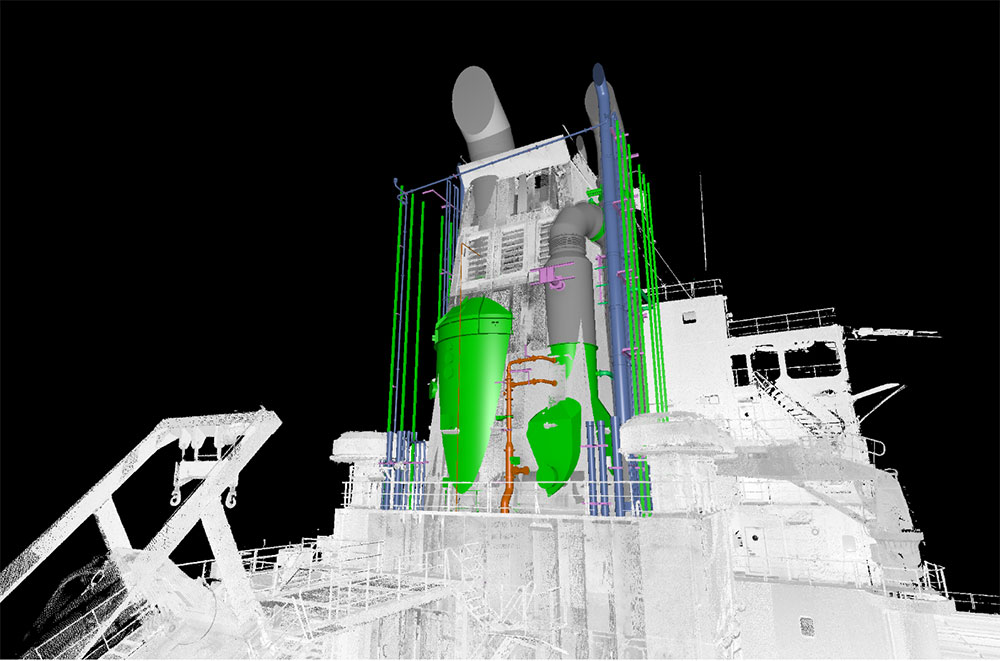

Sox Scrubber retrofit project from point-cloud to real object with Cadmatic laser scan & outfitting.

TTSP have done more than 50 projects for BWMS and SOX Scrubber retrofits, taking the art of reverse engineering to new heights. It has leveraged Cadmatic software to expedite the reverse engineering processes, transforming point clouds into precise 3D models and enhancing project visualization and client communication.

Retrofitting requires high technical skills and special tools such as 3D laser scanners and 3D software. Due to time constraints during rectifications and installation of new equipment, piping and outfitting, proper planning and precession is a must to achieve success.

For checking, the design department and factory utilize eGo for 3D model access, improving accuracy and productivity over paper plans.

According to Mr. Sobrio, the introduction of CADMATIC eShare at TTSP has taken the collaboration between TTSP's design team and the factory floor to the next level.

“Before implementing CADMATIC eShare, our factory staff would visit our office to get feedback and to address design-related inquiries. Now, they can efficiently communicate and quickly resolve these issues with the help of eShare. It has markedly reduced our response times to production issues and has enhanced the overall production process,” says Mr. Sobrio.

Mr. Sobrio concludes by adding that Cadmatic also fosters cross-functional collaboration within TTSP through its Work Request Function, enabling effective communication and resolution of conflicts between different design disciplines. This proactive approach ensures high-quality design output and efficient project execution.

Read more about Cadmatic ship design solutions.