Customer challenge

- Need to reduce the number of printed technical drawings generated for production purposes and provide shipyard staff with more up-to-date information on site.

Scheepswerf Slob implements CADMATIC eShare

Customer challenge

Cadmatic solution

“Overall, we are very happy with the eShare integration. It is easy to use and greatly reduces the amount of emails required. Our production people can now see the status of the parts they need to work with." – Paul Buijs, CADMATIC Hull Administrator

In late 2017, Scheepswerf Slob in the Netherlands implemented CADMATIC eShare to reduce the number of printed technical drawings generated for its production purposes. A further goal was to provide shipyard staff with more up-to-date information on site. Since then, eShare has also been successfully linked with the nesting software.

Scheepswerf Slob implemented Cadmatic already in 1998, when it was still marketed under the Nupas-Cadmatic brand name. The software is currently used to engineer the hulls of superyachts built at the yard and for equipment outfitting.

In the autumn of 2017, Scheepswerf Slob implemented Cadmatic's information management system, eShare. The solution includes a link to the shipyard’s document viewer to export PDF drawings from CADMATIC Hull, like sheet drawings and profile sketches. Outfitting drawings from CADMATIC Outfitting are also available in eShare/eGo.

The implementation was born out of the idea to reduce the amount of drawings that are printed, which in turn would reduce paper costs and give production staff more up-to-date information.

Paul Buijs, the CADMATIC Hull Administrator at Scheepswerf Slob says they wanted to work with a basic set of drawings and supplement the drawings with information on tablets for workers on site. This also meant that the workers had access to more up-to-date production information due to the link to the design application.

“This was a good solution for us. It saves a lot of paper and time and it is very nice to always have correct and up-to-date drawings only one click away,” says Paul.

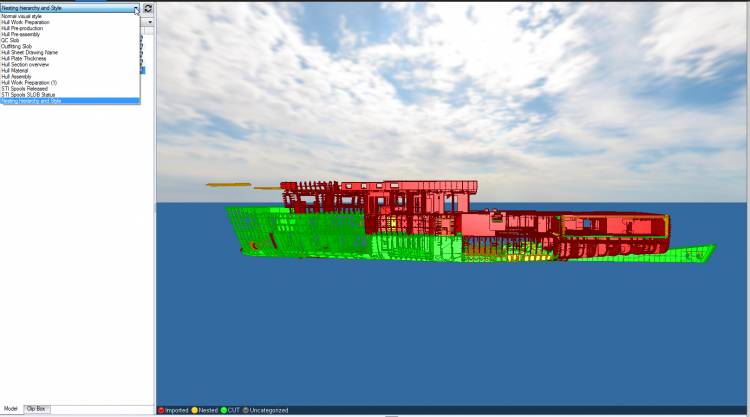

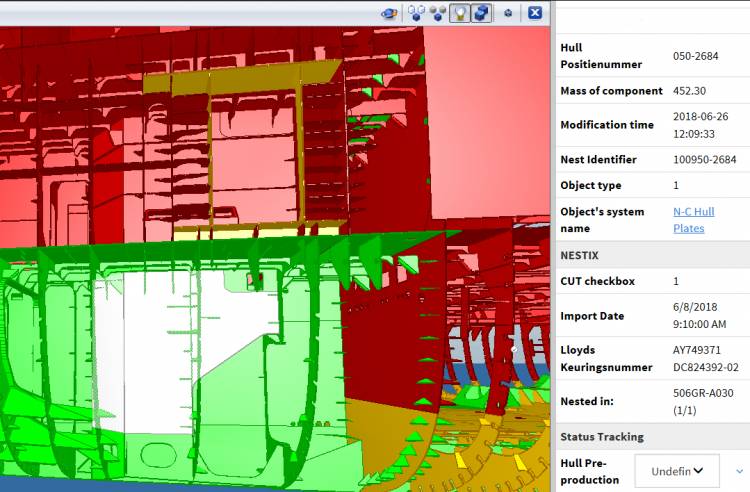

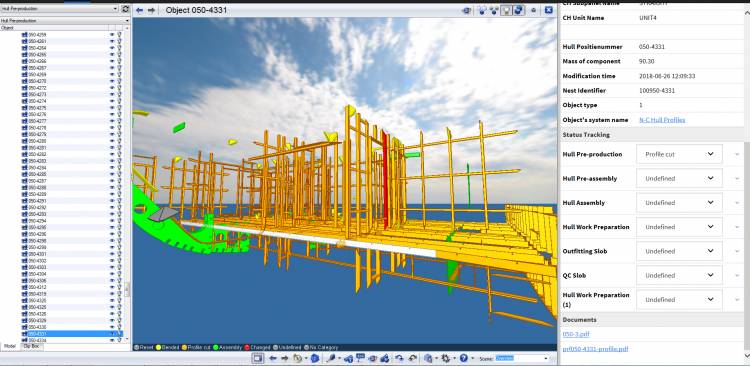

An additional benefit of eShare implementation has been the ability to link the application with Cadmatic's plate nesting software used at the yard. This has enabled Scheepswerf Slob to track the hull building process accurately. See the pictures below.

“With this link between eShare and nesting software we can see exactly what parts have been imported and cut. Everyone can check the progress without the need to request this information from elsewhere. We also can see the Lloyd inspection number of the plate,” explains Paul.

eShare is also applied at Scheepswerf Slob to track the progress of blocks and projects and to facilitate inspection of parts by the foreman on site.

“Tracking the blocks and projects means that all the managers, directors, engineers and project leaders are kept up to date. When everything is visible, it greatly reduces the amount of questions and uncertainties,” says Paul.

Every construction part in the building process is assigned a status, with separate visual styles for all the steps it goes through before it is placed onboard the yacht. With the new 2019T2 version of eShare it is even possible to select multiple objects and simultaneously assign a status.

“Overall, we are very happy with the eShare integration. It is easy to use and greatly reduces the amount of emails required. Our production people can now see the status of the parts they need to work with,” Paul sums up the contribution eShare has made.

Scheepswerf Slob is not satisfied at leaving eShare integrations there: Paul indicates that they have plans to connect it with the shipyard’s Teamcenter PLM software, Siemens Primavera as well as their ERP system Inventive.

Read how your shipyard can gain efficiencies with the digital twin platform eShare.