Customer challenge

- Import laser-scanned point clouds into 3D models to guide design work.

- Share retrofit solutions with customers in light and intuitive format.

Global turnkey 3D scanning solutions for BWTS and retrofit projects

Customer challenge

Cadmatic solution

“Importing point clouds works flawlessly and quickly.” Ernst-Jan Bakker, Senior Project Engineer

With offices all around the globe, Goltens is one of the leading independent global providers of ship repair services. The company’s offices in Dubai, Korea, Shanghai and Singapore have already been using Cadmatic software for some time. Goltens Green Technologies B.V. in Groningen (Goltens Groningen), The Netherlands, implemented Cadmatic software in 2017.

Due to a request from their new Engineering Manager at Goltens Groningen, Mr. Willem Visscher, the company invested in Cadmatic software. Mr. Visscher and some of his colleagues, Senior Project Engineers Mr. Franklin Advocaat and Mr. Ernst-Jan Bakker, had good experiences of working with the software in the past. The decision was quickly made to purchase Outfitting licenses in February 2017.

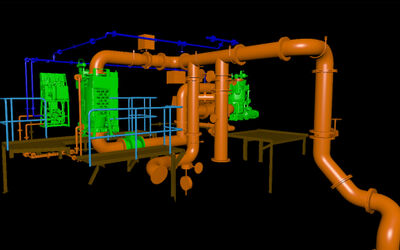

According to Mr Visscher Goltens Groningen is specialized in the implementation of ballast water treatment (BWT) in existing ships.

“We also actively re-design any other system on board, provide production information for hull plates in case of damage, design scrubber installations, or assist with any kind of retrofit”.

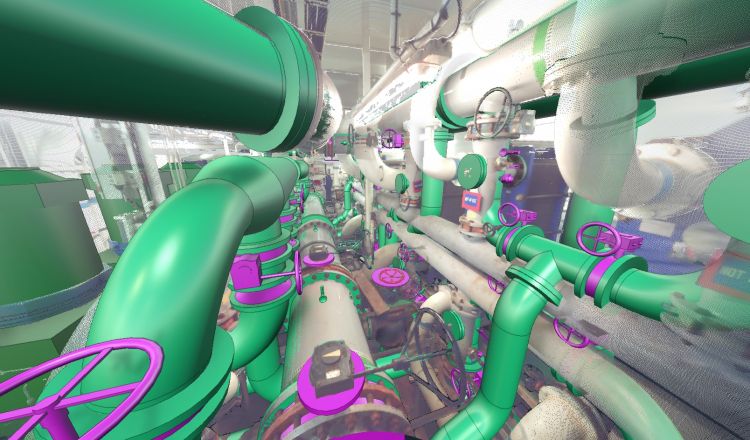

Due to the BWT specialization, Goltens Groningen actively works with laser scanners to scan spaces on existing ships. Laser scanning produces accurate 3D models of such spaces. With laser scanning, a three-dimensional point cloud of the target is created. It offers incredible accuracy and removes most of the risks associated with manual measurements in a very short period of time. Most of the times a port stay offers a sufficient window of time.

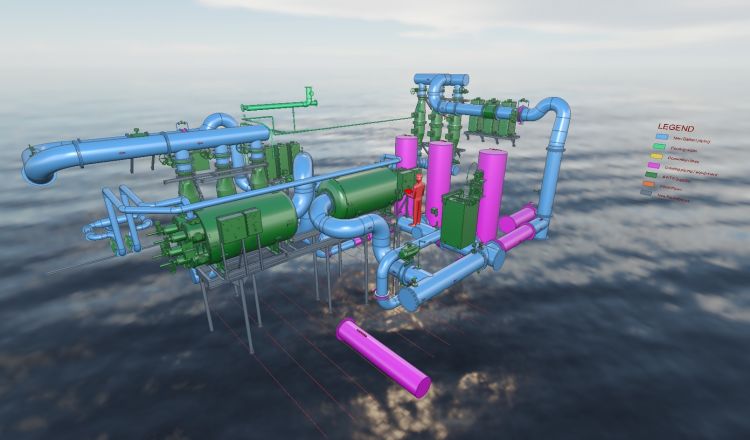

Goltens Groningen works according to a well-proven, flexible process using 3D scanning technology that consists of seven steps. The turnkey solution starts off with system selection, after which 3D laser scanning is done and an onboard survey is conducted.

“The laser scanning process at itself is not that hard, but needs to be done accurately and efficiently, and requires good preparation. Practical experience and know-how, of the ER systems as well of construction is needed,” Franklin acknowledges.

“It is very important to place the laser scanner in several locations to avoid blind spots and put the reference balls, on fixed positions within the space that needs to be scanned”.

After scanning, the next step is importing the point clouds into Cadmatic and publishing them in the project. This is done by the project administrator.

“Importing works flawlessly and quickly, whilst the instructions on how this should be done are clear,” Ernst-Jan says.

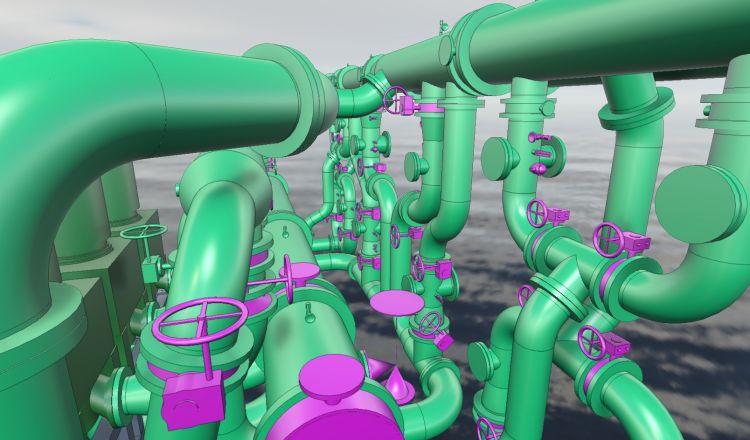

Then, 3D remodeling can be started to create a concept design. After the concept design has been created and an optimal solution has been chosen, detailed engineering can be started.

After detailed engineering, a complete production package including the design and detailed material specification is delivered to the customer. The customer conducts the installation and commissioning as they wish. After installation, ongoing support and service is delivered. In all these phases, CADMATIC eBrowser comes in handy for project reviewing, taking measurements and making markups.

“We can’t do without the eBrowser. It is essential for us to use it for reviewing, to check the retrofitting we have done and to do collision checks. Moreover, it is the ideal tool to present to the customer, how his engine room (or pump room, or deck) will look like with the BWT system installed. Any changes are easily made in this stage if required, and this minimizes rework or surprises at site,” explains Willem.

Modelling in Cadmatic is not new for Ernst-Jan, Franklin and Willem.

“We practically grew up with Cadmatic, so we have years of experience with it. We think that the software works very well and is fast.”

They have seen big improvements in Cadmatic software over the years. One big improvement is the enhanced library including previews. Converting old projects can be done quickly, which saves time, while they describe upgrading to a newer version as “peanuts” nowadays. They are also impressed with the new visualization core, which makes the models visually much more attractive.

Sea cooling water system replacement of a Special Purpose Vessel executed in CuNiFer.

Goltens Groningen has completed over 380 BWT projects. One of the latest projects was the installation of ballast water treatment for the HNLMS Snellius, a hydrographic survey vessel of the Royal Dutch Navy. For this project, Royal Niestern Sander did the installation, making use of eBrowser as well.

Another ongoing turnkey project for the Royal Dutch Navy entails installation of ballast water treatment systems for some highly advanced air-defense and command frigates, also called LCF ships. Demand for Goltens’ services is high, in addition to the projects for the Royal Dutch Navy they have around 20 more ongoing projects for ballast water treatment.

Going forward, Cadmatic will continue to be a core element of successful BWTS and retrofit project implementation at Goltens.

Read how seamlessly and efficiently you can use laser-scanned point clouds in your retrofit projects.

Advanced detail design of the service operation vessel GROENEWIND

Multi-disciplinary quality

Cadmatic helps Glosten think in 3D