Multi-disciplinary quality

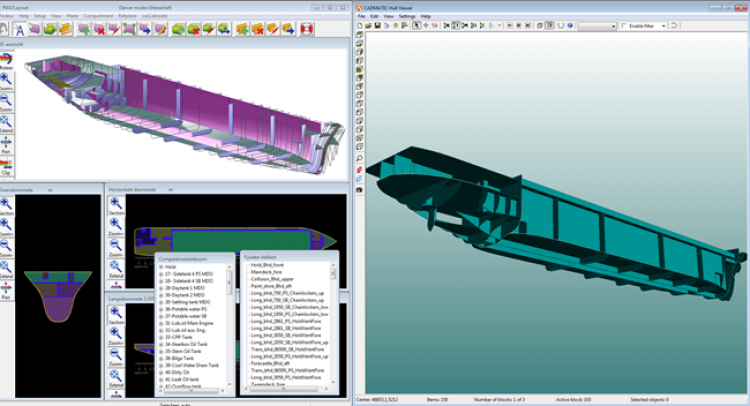

Conoship – 3D data exchange between PIAS and CADMATIC Hull

Getting the most out of Cadmatic software.

Conoship International is a design and engineering office specialized in short sea general cargo vessels. The company is active globally and over 2000 vessels have been built from their designs over their 65 years of existence. Their designs include, for example, the smallest LNG tanker in the world, as well as 14,000 tons of general cargo vessels, dredgers, offshore supply vessels and other vessel types.Process improvement

Mr. Jan van der Zee, a Naval Architect at Conoship, is involved in the company’s basic and detail design phases and engineering. He also participates in several research projects conducted by Conoship and is partly the system administrator for CADMATIC Hull.

“The start-up period was easy in terms of installation, and starting up a new project. What was more difficult, however, was creating the correct norm sets. The administrator needs to understand the importance of the different software settings and how to deal with this to create the correct production information,” Jan says.

According to Jan, designers and administrators get used to the software after a while and then appreciate its benefits.

“Cadmatic software improved our processes so that we are now able to deliver detailed production information for complete building packages in a concurrent time frame”.

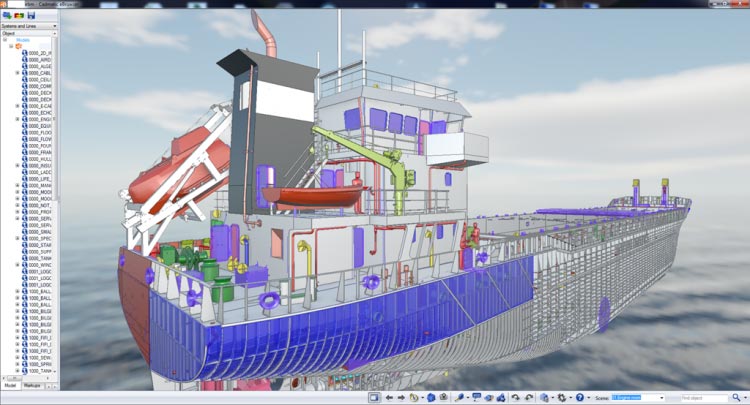

Conoship also benefits greatly from eBrowser in completing the ship design process; eBrowser provides designers and project participants with insights into the project, starting from the early stages of design.

“eBrowser doesn’t only give us the opportunity to view the progress of a design and give comments, but also gives our clients and subcontractors this opportunity as well,” Jan continues.

A consistent and error-free model

During the SMARTYards project, a two-way 3D data exchange between PIAS and CADMATIC Hull was created. The CADMATIC Hull model was linked to the PIAS stability model and with the exchange functionality they were able to exchange the necessary data between the software programs.

Quickly thereafter, based on the watertight model in PIAS and the integration with Cadmatic, Conoship was able to start routing pipes and placing equipment in the Cadmatic model of a general cargo vessel at the very early basic and preliminary stage of the project. Any collisions and difficulties could easily be identified and solved to keep the Cadmatic model consistent and error-free. At the moment of writing, Conoship has almost completed the design of this general cargo vessel, in which they were responsible for the complete outfitting design of the model. The initial steel design was set up in CADMATIC Hull.

Enthusiastic about Cadmatic

Conoship is very enthusiastic about modelling in CADMATIC Hull and Outfitting. Modelling a complete ship in 3D prevents errors and provides good insights into the design. They also appreciate the CoDesigner functionality.

“The collaboration with other Cadmatic engineers and companies is working very well, thanks to the distributed design capabilities of Cadmatic. We are using CoDesigner in multiple projects at the moment. It is very beneficial because the design data created by various parties is available directly, so possible errors can be identified and solved quickly,” Jan explains.

Getting the most out of the software

Conoship’s Cadmatic engineering department is still growing. Its young, yet experienced engineers aim to get the most out of Cadmatic software. They want to learn about and apply every function possible that improves the design and engineering process. Some examples are: finding the best way to present product information, improving weight estimates and keeping track of the weight of the vessel and improving the connection with the concept design phase to set-up a Cadmatic model as early as possible. In that sense, the cooperation between Cadmatic and PIAS also plays an important role.

The connection between these applications is being further developed at this moment in the Dutch Collaborative Platform for the Design and Engineering of Ships (CPDES) research project. Cadmatic, Conoship International and SARC are collaborating to develop a collaborative ship design system on the project. Conoship also provides Cadmatic developers with useful feedback in improving the software.

When asked whether he would recommend Cadmatic software to other companies, Jan responds “yes, definitely, because Cadmatic offers an extensive set of tools to create and elaborate on the widest range of different ship designs, providing the information designers and engineers need at every stage of the design”.

Read more about Cadmatic ship design solutions

Read more about how your design company can also benefit from Cadmatic's powerful ship design software.

Read more customer success stories

-

Multi.Engineering – Over 20 years’ design excellence with Cadmatic

Read more -

Gondan – Hull & outfitting design and design review tool eBrowser

Scaling new heights with Cadmatic

Read more -

Bluetech Finland – Innovate approach to 3D hull basic design for 158-meter RoPax

Rethinking basic design

Read more