- Number of floors: Tunnel, basement and 5 floors above ground

- Floor area: Approx. 20 000 m2

- Connects to 7 other buildings in the hospital campus

- Number of wards: 12

- Design documents: 549

- Floor plans (Electrical + separate tele plans): 122

- Distribution boards: 120 main boards

- Diagrams: 550

North Karelia Central Hospital

CADMATIC Electrical used in large renovation and expansion project

The first construction phase of an ambitious renovation and expansion project of the E-wing of the North Karelia Central Hospital in Joensuu, Finland, is set to be completed by July 2024. The electrical design of the project was done by Finnish construction and real estate sector company Granlund, while Caverion Suomi is the contractor responsible for the electrical installation. Both parties have used CADMATIC Electrical extensively during design, coordination, and installation work on the project.

The total area of the repair and expansion project is approximately 20,000 m2. The revamped E-wing will include logistics, imaging, medical technology, clinics, a sobering-up unit, operating departments, a maternity ward, and a postnatal ward. Construction started in the summer of 2022 and will be completed in the summer of 2026. About 65% of the building will be completed at the end of the first phase in July 2024.

The project presented unique challenges, particularly in executing construction within an operational hospital environment. CADMATIC Electrical played a critical role in addressing these complexities, and its robust and reliable features significantly eased the design process. The software's ability to handle detailed modelling was crucial, especially considering the project's need to accommodate a variety of hospital facilities and technical systems in a confined space.

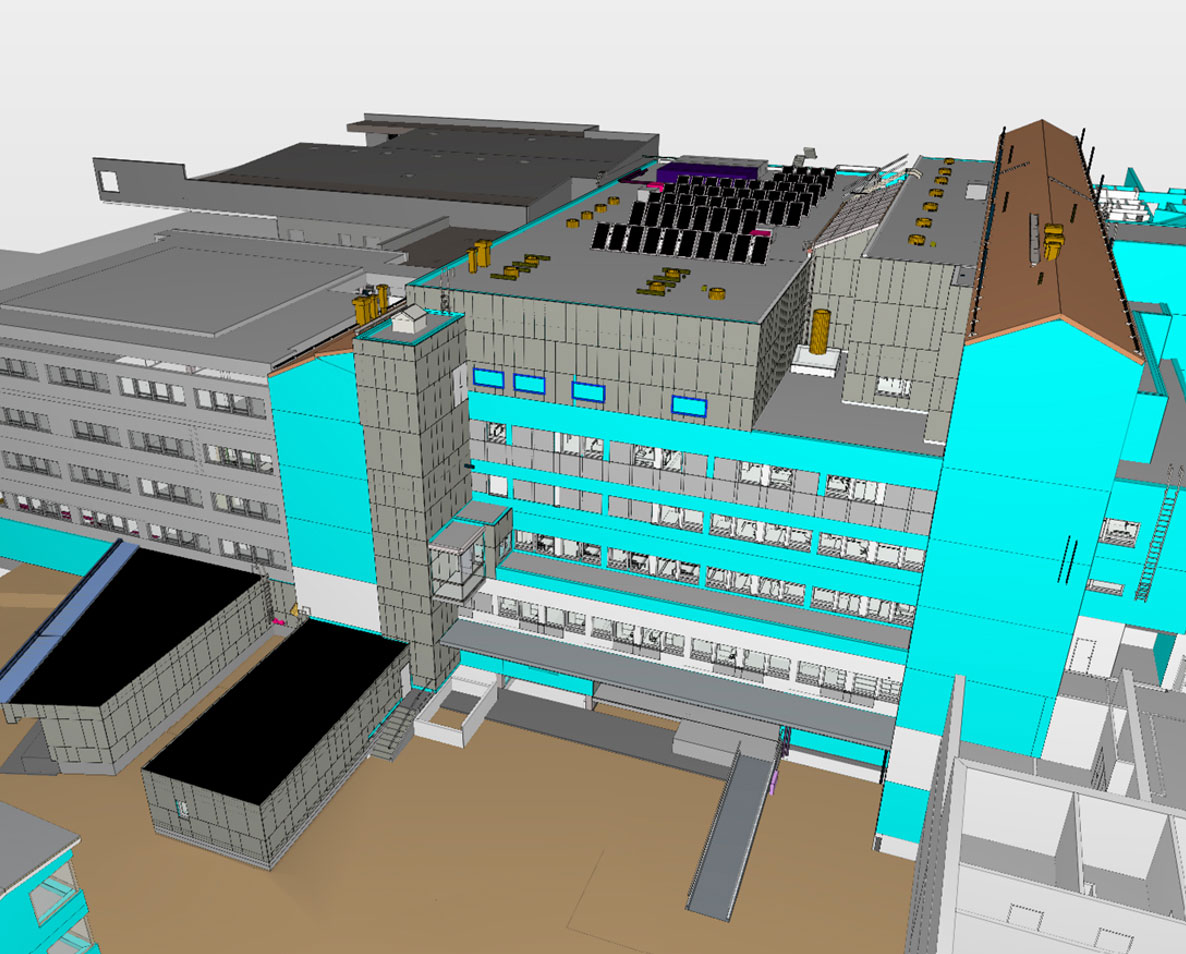

Old and new parts of the hospital with all design disciplines combined into one 3D model.

Project details

- Dali devices: 2243

- Socket outlets:

• Normal 2716

• Generator backed-up 728

• UPS-backed up 350 - Luminaires: 3226

- Cable trays: 10 km

- Trunkings: 2km

- Power supply cables: 13km

- 10 designers from three different locations across Finland.

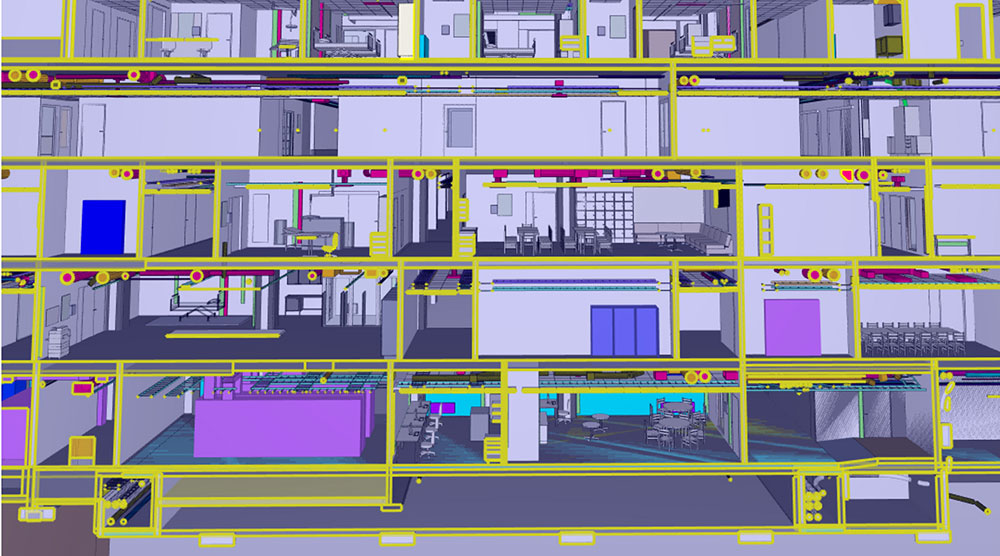

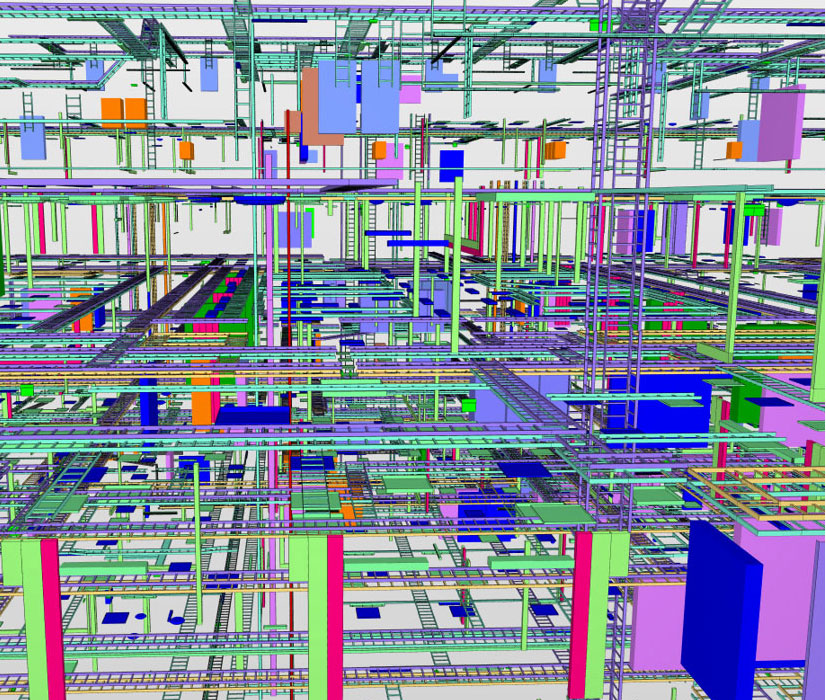

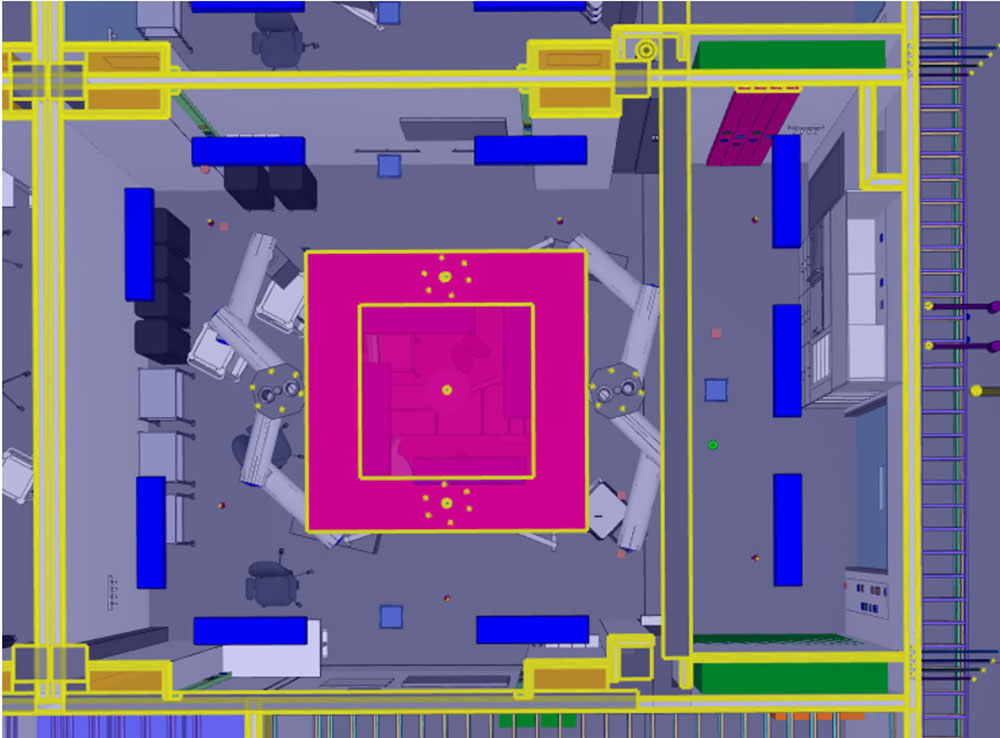

Most of the electrical network is distributed in fake ceilings. A BIM model coordinator checked the model for potential collisions between electrical and HVAC elements.

3D modeling a key success factor in challenging design project

According to Niko Hellberg, Group Leader at Granlund, most of the design work, which started in 2018, was conducted inside the existing hospital structure that was built in multiple phases between 1950 to 1980. This came with its own set of challenges due to the low room heights from that period, which nevertheless must accommodate an extensive and modern electrical network in fake ceilings with limited space.

Niko says the need to keep one side of the hospital in operation while the other is revamped created additional demands related to the existing electrical network. Careful consideration had to be given to ensure uninterrupted operation of surgical wards, telecommunications, and other technical systems and networks.

“3D modelling in CADMATIC Electrical played a crucial role in assisting us to fit in all the electrical equipment and cable management elements. The highly detailed electrical models included, for example, power outlets and switches and required a lot of work. A BIM model coordinator combined the electrical model with the architectural and HVAC models to check for any clashes between the disciplines,” says Niko

He adds that the continuous collision testing and related weekly reporting ensured that any corrections were immediately made as soon as clashes were noticed. This meant that no major alterations were needed during installation.

Caverion Project Manager Henri Honkanen agrees, even though he says that on a project of this scale, it is virtually impossible for everything to be perfect.

“We noticed some very small clashes during installation, like a cable tray that clashed with a ventilation duct or a beam height that was somewhat lower than what was imagined during the design phase. But we fixed those rather easily and overall, the design was very accurate,” says Henri.

When asked about what he appreciates most about CADMATIC Electrical, Niko mentions its reliability and the convenience of working with an electrical software program that has a fully functional Finnish-language version in addition to the standard English-language interface.

“You can trust the software, it is robust even in large and challenging electrical projects like the Joensuu hospital,” says Niko.

The CADMATIC Electrical 3D model. Designers create multiple IFC files (raceways, electrical outlets, and light fixtures) for every floor and combine them into one.

CADMATIC Electrical a key tool during installation

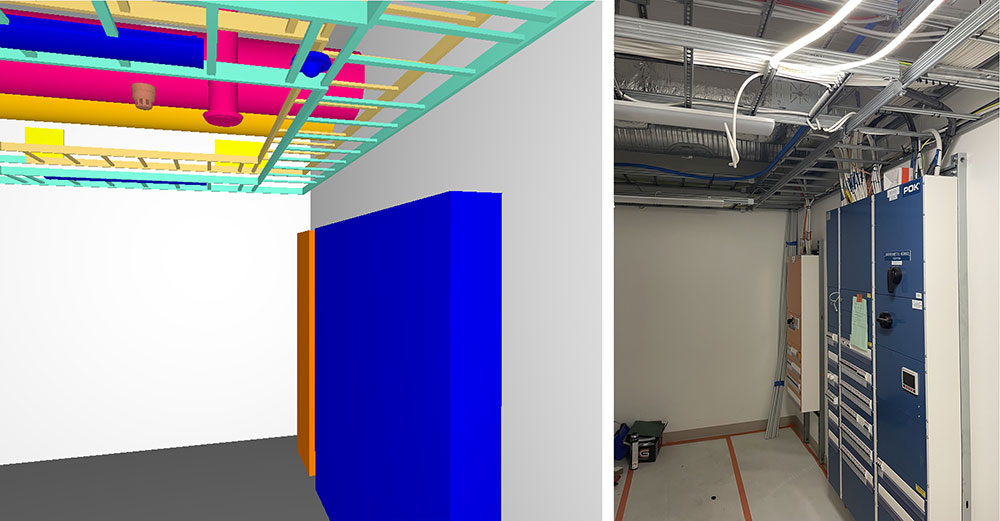

Henri Honkanen indicates that Caverion’s electrical installation staff have accessed CADMATIC Electrical 3D models via tablets during installation to check installation details and to move around virtually inside the 3D model.

“We use Dalux software on site to check 2D drawings. When our installation people click on the drawings, it opens the 3D model from where they can see all the required information, check heights, take other measurements, and compare the model with the floor plan.”

He adds that a great benefit of working with the 3D model on site is that you can see all the equipment and systems at the same time.

“It is especially difficult to grasp the height of objects from 2D drawings, but from the 3D model it is immediately clear, and you can see what different systems and pieces of equipment should look like after installation,” says Henri.

Quantity takeoffs and accurate measurements

The detailed electrical project and interlinked 3D model were also used for quantity takeoffs, which is especially useful when you need to locate a few pieces of equipment that could be anywhere in the building.

“It’s a very large building, so if you are just looking for a few specific pieces of equipment, you don’t have to search the floor plan or look for the right symbols. You can instantly locate the objects in the project tree in CADMATIC Electrical by simply entering the device ID and navigating to the object,” Henri explains.

A lot of measurements were also done in CAD, which both Henri and Niko indicate is highly accurate. They recall one challenging 300-metre-long cable that had to be laid between sets of compressors.

“In such cases, one can expect that your measurement could be somewhat off, but when we did the installation, it was exactly right, which meant that we did not waste any cabling materials,” says Henri.

The old operating theaters were fully functional during construction behind the walls. In the second construction phase (July 2024 onwards), the new operating theaters will also be fully functional while construction continues.

Hero image credit: Tiia Monto, CC BY-SA 4.0 via Wikimedia Commons