The power of copying in process industry projects

Don’t waste time on re-design in industrial design projects, copying is an excellent way to achieve more and improve efficiency.

Posted on October 28, 2020

Increasing efficiency and getting the most out of limited resources is an eternal challenge. In industrial design projects, copying is an excellent way to achieve more and improve efficiency. CADMATIC’s sister project management supports parallel work in sister projects with flexible change management.

Benefit from work that has already been done

Copying is widely used in large industrial projects to build factories or ships. Ideally, sister projects should be implemented as they allow leveraging significant amounts of work that was done before; the unknowns are known while the resources, manning and all other operations are understood and balanced.

The time and cost savings associated with sister projects are the major drivers behind their use. The savings make sister projects desirable, but also very challenging. Project size, complexity, financial pressures and strict delivery deadlines contribute to making sister projects a significant challenge.

Efficient change management a key success factor in sister projects

Efficient change management is a key success factor in sister projects. With multiple sister projects and a longer project timeframe, the challenges increase exponentially. Copying would be easy if the projects involved were identical, but this is rarely the case. Different types of equipment might be chosen to match updated performance specifications while different part suppliers or materials can cause changes in layout and construction requirements. Updated work processes at subcontractors also require updated output documentation.

It is challenging to manage the construction of sister projects in an industry where change is the only constant and design is increasingly complex. Projects commonly follow each other on a continuous production line and schedules usually overlap.

Improvements can be implemented downstream

Despite the above-mentioned challenges, the use of sister projects does allow possible design flaws identified on a project to be corrected in the following projects. Better or more cost-efficient solutions may similarly be identified and implemented. Changes in legislation, specifications, or standards may also necessitate changes from project to project.

The simplest possible scenario is when project schedules follow each other with no overlap. In such cases, the design of the parent project can be copied in full to the next project, after which the necessary changes can be made to the copied project. The first project may already be in operational phase, but still require modifications due to problem areas. This, in turn, means that the modifications also need to be made to the ongoing sister projects.

Designing sister projects in a synchronized schedule brings additional savings in time and costs while adding complexity in management. The benefits depend mainly on how well the design phase can manage changes. Without sister project management, the same changes have to be made several times in sister projects.

The benefits of using the sister project concept by CADMATIC:

- Avoid errors with better coordination by utilizing previous design work

- Quality improvement due to fewer errors

- Agility – mother project changes can immediately be seen in sister projects

- Reduce working hours when project or part of project is copied

Similar, but not identical

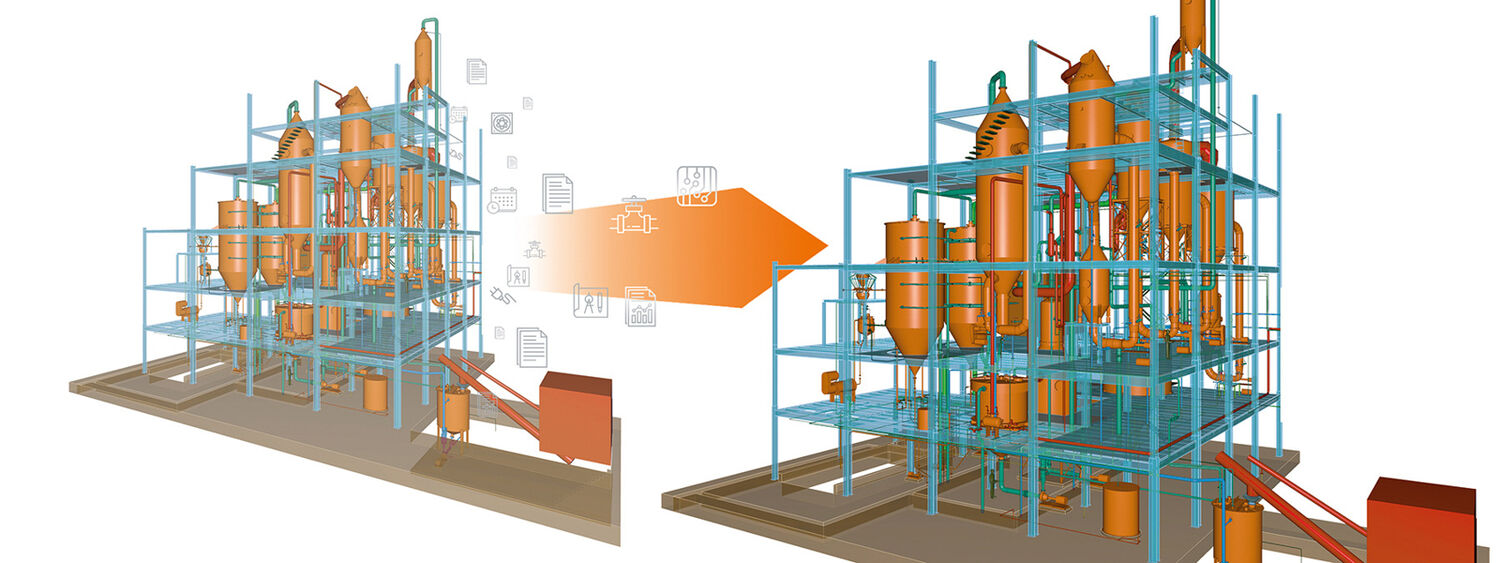

Sister projects are similar, but not identical. When something needs to be changed in the target project, the links to the parts in question are removed, after which target project-specific planning can start for the unlinked parts. Parts and drawings can be copied independently. At the end of the process, unique and up to date 3D models and documentation exist for each project.

Several sister projects can be created from the same parent project, or a sister project can be designated as the source of the following project. Projects can also be combined and different parts from several sources can be copied to one target project. This way, one part of a project can come from the original parent and another from an earlier sister.

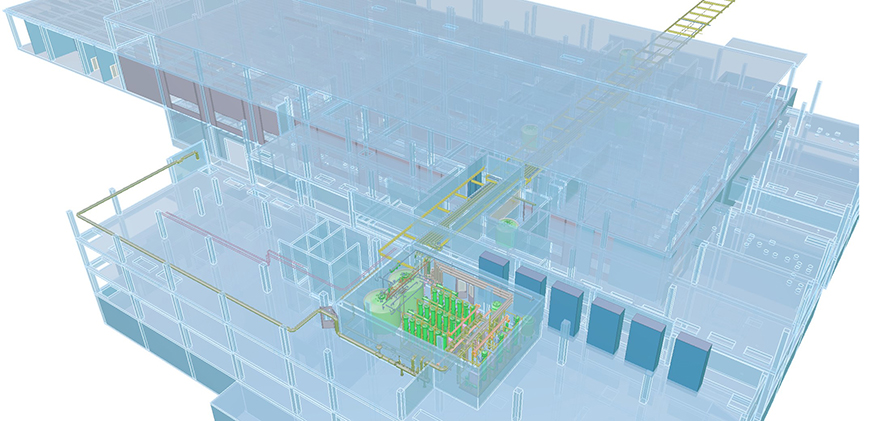

It is also possible to visualize differences in projects by loading sister projects to CADMATIC eBrowser to compare the 3D models and meta-data of all 3D parts in the model.

Summary

Reusing experience, 3D models and documentation from previous projects helps to reduce design hours and the needed support from CAD tools. CADMATIC’s flexible approach facilitates the process for users and provides the required tools and the possibility to link with PDM/PLM or ERP systems for efficient execution of EPC projects of any complexity.

The greatest efficiency can be achieved by using 3D plant design tools together with available interfaces and information management.

It is also possible to visualize differences in projects by loading sister projects to CADMATIC eBrowser to compare the 3D models and metadata of all 3D parts in the model.

Read more about CADMATIC software solutions

Read how you can gain efficiency with CADMATIC 3D Plant Design.