Multilateral plant design collaboration equipping future engineers with CADMATIC design skills

Posted on April 18, 2019

When the Metropolia University of Applied Sciences implemented CADMATIC 3D plant design software in educational use, the course included a practical assignment at the Sappi Kirkniemi Mill under the guidance of consulting and engineering company Pöyry. A digital twin of the mill designed with Cadmatic has been maintained at the site since 1995. The dedicated training benefits the students immediately, and in the long run, it will benefit companies in need of design services as well as the employment market and economy.

CADMATIC’s long-term cooperation with consulting and engineering company Pöyry and the Sappi Kirkniemi Paper Mill was reinforced when the Myyrmäki campus of the Metropolia University of Applied Sciences chose to use CADMATIC software as part of its plant design course and studies. The design system does not require client installations and can be accessed from 30 workstations at the school, using licenses worth about 400 000 euros. CADMATIC provided an introduction to the course, which was attended by 58 students. The practical assignment for the course included the design of a raw-water pump for the Sappi Kirkniemi Mill, where a 3D model created by Pöyry using CADMATIC has been in use since 1995. The course also included student visits to the factory.

“It is important for educational institutions to provide training directly based on industry needs and practices, not only on theory,” says CADMATIC sales manager Jim Nyroos.

“In addition to Metropolia, we have previously collaborated in a similar manner with the Turku University of Applied Sciences. I am sure that the engineering students are grateful for the opportunity to create designs for a real purpose using advanced tools, as this experience will effectively prepare them for employment. Real assignments and advanced tools are important for schools when competing for the best talents. In time, the increase in human capital will impact industrial competitiveness and thereby economic growth. From the point of view of the engineering company and the mill, the collaboration with the educational institution will improve their employer image as well as recruitment potential.”

The first ever plant design course of this type in Finland

“This course has been a unique opportunity. Nothing like this has ever been organized by an educational institution in Finland before,” notes lecturer in chemical and process engineering Timo Seuranen of Metropolia.

According to Seuranen, the thanks for the initiative go to the PSK Standards Association’s PSK24/2 piping design team and executive director Jukka Koistinen.

“Through the PSK development unit, the representatives of Finnish industries commit to supporting education and hands-on practice.”

“This is the first time that chemical and process engineering students participate in plant design training, and five of the participants have already been recruited,” Seuranen says. “Installing the software in the school’s workstations was a long process, but the CADMATIC representatives have been flexible. We have Pöyry’s Mika Pirttinen to thank for the Kirkniemi Mill assignment. For security reasons, the visit by more than 50 persons to the factory to learn about the process was a rare opportunity, and we are very grateful to Sappi for that.”

“The three days of software training by Henri Särkkä of CADMATIC was an excellent and effective introduction to the project,” Seuranen continues.

“All of the enrolled students were present, committed to the course and learned to use the software at a sufficient level. We would like to continue and expand the collaboration and the concept to energy engineering and biotechnology, for example, even if updating the curricula and building the necessary relations is a time-consuming effort. There is great demand for skilled employees in the industry, and young people are highly motivated to obtain an applicable education. It is a major advantage for companies to receive software-savvy recruits fresh out of university, and CADMATIC is intuitive and easy-to-use software developed in Finland.”

Quick software learning experience for an exceptionally large teaching group

“We’ve received great feedback about the course from both Metropolia staff and the students,” says the course instructor, application specialist Henri Särkkä of CADMATIC. “Universities of applied sciences usually cooperate with local companies and provide employees for their needs. However, it is important to expand the practice to other industries and regions, too. Using basic software tools cannot be avoided at work, and hands-on experience is necessary in addition to software skills. The students need to see what engineering is like in practice and why certain tasks need to be completed. An actual assignment provides a realistic idea of what design work consists of in practice.”

“Our software has been praised for being very easy to learn,” Särkkä continues. “The skill level required for plant design can be achieved in about one week. This was an exceptionally large group that included a wide range of skill levels, but I was surprised by how quickly the group were able to start using the software. Nobody fell behind, and everybody seemed to realize what was being done and how to perform certain functions. The main point of teaching was to help them understand why certain aspects are displayed in a certain way in the software. In my opinion, applied science education provides good prospects for Finnish plant engineers.”

The training course used an easy-to-share software license structure, and the students were also able to use the software on their private computers, with a VPN.

“I was fairly impressed to hear the students ask whether they could use the system in their own time and where they could find further information,” Särkkä says. “During the course, all users committed 100% and proactively, even if their ages varied from 20 to 40 years.”

Clear demand for plant design competence in Finland

“There is a need for plant design training in Finland in order for the students to learn the realities of engineering work,” confirms engineering manager Mika Pirttinen of Pöyry, who guided the practical assignment for the mill. “It is not clear to many engineers how to design a factory with piping based on their basic training. Pöyry delivers engineering projects all over the world, and there is a great demand for new specialized designers. Graduates with hands-on experience easily find employment in engineering projects. In addition, we have our own two-year Pöyry Stars career path program, in which some of the students on this course are also participating.”

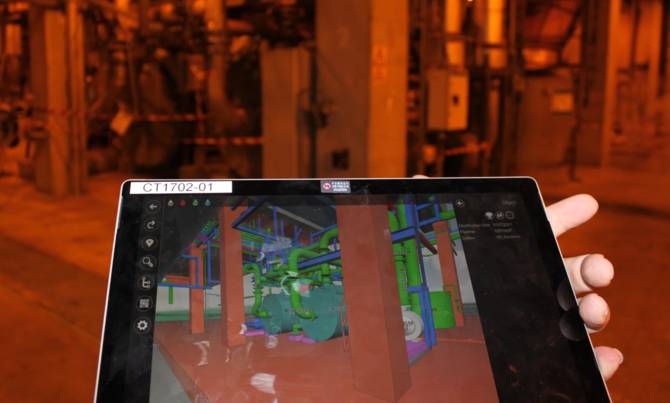

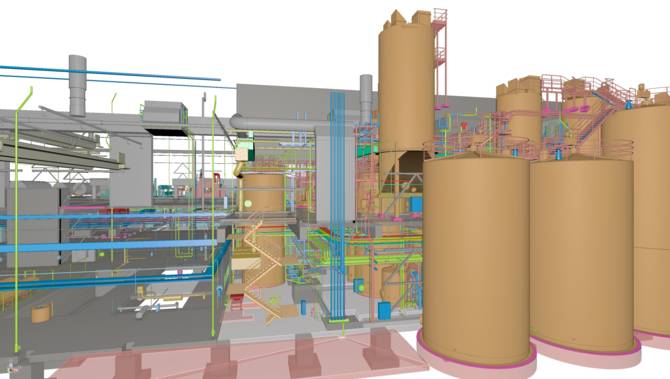

“The Sappi Kirkniemi Mill provided an actual need for conversion in order to improve the paper production process,” Pirttinen explains. “The visit to the factory provided an opportunity to see the real environment and understand how the model compares to reality. At the factory, the students were expected to make notes on what to consider when designing the new pump. These issues, which include space reservations, changes in piping and ease of maintenance, were discussed in advance during the course.”

3D modeling is standard in plant design

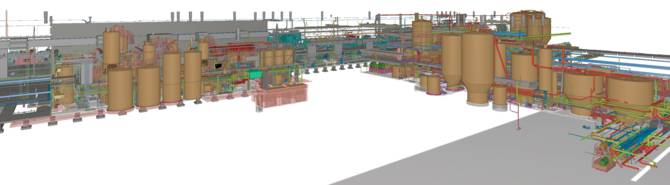

“The Sappi Kirkniemi Mill was the first large paper mill in the world designed completely using 3D modeling,” says Kai Vikman, chief operating officer at Pöyry Finland. Vikman was the project manager of the Sappi mill project in the mid 1990s.

“At the time, the project was unique for both engineering offices and the industry; perhaps not technically, but in terms of implementing 3D design. After that, all major engineering offices moved on to model-based 3D plant design. Factories have abandoned 2D design, and today’s design is all about digital twins and integrated building information models. Along with the development of cloud technology, communication has improved and become faster, but the basis for all this was created already in the mid-90s. And model-based design is at a world-class level in the Finnish construction industry, too.”

“The Kirkniemi factory was also the first modeled plant to integrate the model directly with management systems and databases using SSOT, Single Source of Truth. The model created at the time is still in use and accessible online wherever, which makes spare-part procurement and change management, for example, much easier,” Vikman notes.

“Involving students and institutions in the modeled factory environment significantly helps developing plant design teaching and standardizing ways of working. Design must aim at safety, efficiency and ease of maintenance. It is truly worthwhile investing in competence, knowhow and understanding of young engineers. It allows us to achieve the competitiveness needed on the global markets,” Vikman concludes.

Support of training will pay off in the future

“The course assignment involved designing a raw-water pump we need to feed lake water to the heat exchangers of a paper machine,” explains project engineer Christer Råbergh, who has worked at the Kirkniemi Mill since 1995. “The purpose of raw water is to cool the process water that is too hot to be sent to the water treatment utility. A warm summer is the most challenging season regarding cooling. In order to increase capacity, the pump needed to be designed and dimensioned anew, which requires changes in piping. The space for the pump is only about four times four meters. The pump is expected to be completed in 2020.”

The PK3 paper machine and special pulp mill (EMT) at Kirkniemi were designed using CADMATIC software, the factory started operations in 1996.

“After that the model has been extended with a grindery, a thermo-mechanical pulp plant and a reject plant as well as the first parts of the PK1 and PK2 paper machines,” explains Råbergh. “In principle, sections are added to the model every time something new is designed or something old is changed. At the time, CADMATIC was chosen for the job perhaps partially because it is a Finnish software product. The benefit of ordering the pump design as a practical assignment is low to us at this point, but it will increase in the future when new specialists enter the field. At the moment, our resources at the factory are tight, and our main task is not to educate but to produce paper and maintain the equipment. However, there are not many CADMATIC designers outside the capital area of Finland, and the factory prefers to use local skills. It would be ideal if plant design specialists were available near the factory in the future.”

“Our cooperation with Cadmatic started in the mid 90s and continues to this date,” confirms engineering manager at the factory Rauno Timperi. “Kirkniemi was the first 3D project, after which the model has been extended step by step. The largest engineering offices have moved on to 3D plant design as the technology has developed, and the visit to the factory was a unique opportunity for the students to compare the modeled environment with reality. This type of cooperation will create more Cadmatic users in the future, in which case various industries will benefit from plant design competence.”