eShare digital twin platform - strong support for construction phase

Addressing information management challenges in EPC and asset management projects

Posted on October 27, 2019

A picture may be worth a thousand words – but an interactive 3D dashboard answers thousands of questions and helps to facilitate EPC projects. Integrating 3D, 2D, and data from constructability and site management systems allows CADMATIC eShare to take a central role in the project management process.

Complex engineering and construction projects are often split into phases, each focusing on a particular goal. The phases include FEED, detailed process design and engineering, constructability analysis, the generation of documentation for construction, change management, as well as project handover and asset management.

Different teams or subcontractors produce a range of data with the goal of ensuring that the project is completed and that the target budget and deadlines are met. Two main factors contribute to the complexity of the process: cooperation between project teams with different functions, and differences in information types and formats produced.

Due to the divergent nature of the work, different types of documentation are sometimes produced and stored in different systems. Together, all these factors lead to information that is distributed in different bits and pieces, sometimes in files, sometimes in databases. Occasionally, this data is stored in document management systems, or simply in file directories in shared drives, or on an intranet. Some project information can be classified as tacit information, which exists only inside people’s heads because they have no time or means to “attach” it to other project data.

The data is linked and can be easily accessed, searched for, and visualized without the need to move it from origin databases and systems or validate it.

The digitalization trend aims to resolve these challenges by unifying access to information and resolving differences in information storage formats. The discussion about digital twins has revolved around the search for a universal approach to storing all data related to as-build and as-operating process plants. However, the latest research in this area advocates for a more realistic approach of creating digital twins for specific use cases, instead of a universal one. An all-purpose digital twin would lack functionality specific for diverse project phases or have too much unnecessary data, which would lead to fuzzy and misleading information for end users.

CADMATIC eShare provides a platform for collecting digital data related to industrial design and engineering, construction, procurement and operation data, without the need to relocate data from systems that are already in use. The platform supports specific use cases tailored to EPC and owner-operator goals.

3D information model as interface to project-related data

The 3D model contains a large amount of data that is used for the post-design phases. However, it is often difficult to access for people who do not use CAD software and only need partial information from the design stages. eShare combined with eXchanger converters allow the combination of models from various formats, such as PDMS®, PDS®, S3D®, DWG, IFC, and more. Additionally, it is possible to upload data from laser scanners, adding a photorealistic as-build element to the 3D model. This allows the user to get a complete project in one window, even in cases where subcontractors and different disciplines use different CAD systems.

eShare provides access to the various types of information via one window: the 3D model, 2D drawings and documentation, overlaying layers of data such as data that is added to objects from constructability analysis, or tracing construction progress. The data is linked and can be easily accessed, searched for, and visualized without the need to move it from origin databases and systems, or validate it.

A lot of knowledge needs to be communicated to non-engineers and using the 3D model as a hub of information provides an intuitive interface for this purpose. One picture is worth a thousand words, and a 3D model conveys more information than flat data tables.

The rapid development of IT infrastructure and software allows all data to be presented not only in a web portal, but also on tablets to take on site or to be used with HoloLens© for augmented reality tours. With eShare add-ons, all this is possible already – using eGo on Windows tablets and eShare for HoloLens makes complete project data available in the most suitable way.

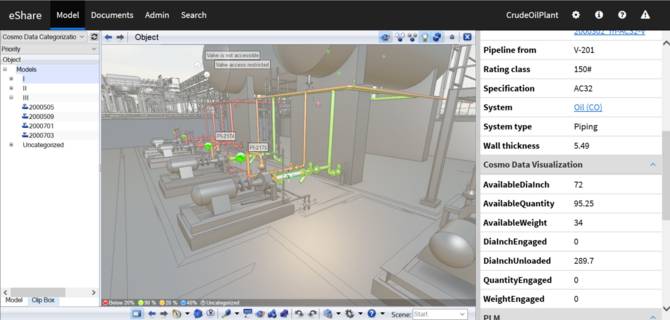

3D dashboard to constructability information – select model hierarchy according to building priority categories and color based on constructability analysis data.

Supporting constructability review with 3D models

The 3D model provides powerful visual support for constructability reviews. Constructability analysis is usually performed in specialized applications, such as work packaging, COSMO5®, or other similar systems. However, the data is difficult to work with in its traditional form, as it is often in numerical format and not visualized. eShare successfully solves this challenge by linking analysis data with the 3D model and visualizing the data. With a few clicks, it is possible to color parts of the 3D model according to constructability levels, with consideration for the calculated storage data values, shipment forecasts and warehouse data, piping fabrication, dia-inch pipeweld data, or any other relevant information.

Planning and scheduling for construction phase

Linking 3D engineering data with construction-phase scheduling improves overall project progress. Often, one part of the project is still in the design approval stage, while others are already scheduled for construction. Having the latest and complete documentation in the same window allows project managers to avoid costly mistakes. Site managers can monitor construction schedules, detect late deliveries early, expedite materials, and reschedule work packages as necessary.

A 3D model hierarchy based on defined construction priorities can be created. This enables the user to see what parts need to be constructed and in what order. Adding color-coding according to constructability analysis visualizes expected delays due to late material arrivals. This way, work packages can be redefined, and installation teams’ schedules corrected as early as possible.

Collect notes from installation teams and use color-coding to visualize the installation status of the model in eShare.

Monitoring construction progress

With the use of the 3D model as a dashboard, site planners can keep track on prefabrication and construction activities and constantly monitor the availability of materials in warehouses and shipping documents. Taking the 3D model on site with eGo on a tablet adds mobility and enables front-end inputs. On-site, information about installed items and pipelines can be easily marked in 3D and later synchronized with eShare to become available for all other project parties.

The updated installation status is critical not only for project management, but also to avoid design changes in locations where there are already installed parts, or at least to ensure that re-installation work is minimized.

Project communication channel and change management with visual support

The 3D model can be used as a discussion board to facilitate project change management and control the construction phase and planning. It is possible to store comments saved on top of the 3D model with labels and dimensions, compare the model with previous versions, or send an email with the attached picture.

The certification process from equipment suppliers can also be monitored with the visualization of status information. Smart points in the model can store silent knowledge or even be linked with data from instruments. The extensive search functionality allows the location of any needed information and any data from eShare can be used for visualization purposes.

Adding value for owner-operators: asset management and operation support

eShare offers a platform to host a digital twin of projects. Besides consolidating all project-related data in one web portal and providing the most innovative technology for efficient handling of large 3D models in various formats, eShare ensures that any information is available in the optimal format to support decision-making.

Inspection data can be linked from maintenance systems and visualized without additional integration efforts. Any data can be added to eShare, irrespective of the storage system and database format. This includes data from maintenance systems or online streaming data readings from sensors. Once linked to eShare, it can be easily visualized and used alongside other project information. Notifications about abnormalities in operation can be handled more efficiently if data regarding normal values, maintenance history, manufacturers’ manuals, process diagrams and 3D models are available just a click away.

eShare - linking 3D model with online data from sensors for asset management.

eShare in brief

- One window provides access to all project related data

- Converges engineering 3D models with constructability analysis, construction scheduling and progress follow-up

- Links to asset management systems and provides platform to store digital twin

- No need to move, validate and copy data

- Intuitive user interface with 3D visual support

- Fast implementation – easy to take into use