Customer challenge

- Need for consistent CAD solution from P&ID to isometrics through to plot plans.

- Need for powerful CAD tools at price and licensing terms suitable for small engineering company.

Gaining efficiencies with CADMATIC Primary

Customer challenge

Cadmatic solution

“The pricing of CADMATIC Primary makes it very competitive and was a significant driver for us." – Vincent Doucet, Technical & Innovation Director

Engineering and design company ValoSys from Pau, France implemented CADMATIC Primary in the second quarter of 2019. The company’s Technical & Innovation Director Vincent Doucet reports that the software features and cost-efficient Primary package match their needs well. ValoSys engages mainly in projects for the chemical industry and gas treatment in oil and gas and biogas sectors.

The ValoSys search for a consistent CAD solution from P&ID to isometrics and through to plot plans started in early 2019. After evaluating different solutions, they decided on CADMATIC Primary. The software is used for process flow diagrams and P&IDs from which various lists are extracted: equipment, valves, instruments, pipes. They also do the general installation of equipment, steel structures layout and pipe routing between equipment with Cadmatic.

Vincent Doucet indicates that the cost-efficiency of the CADMATIC Primary package was a big drawcard when ValoSys selected the software to support the company’s development.

“The pricing of CADMATIC Primary makes it very competitive and was a significant driver for us. The only limitation is on the number of model objects, so in the end it is related to the project size. So far it fits our needs perfectly,” says Vincent.

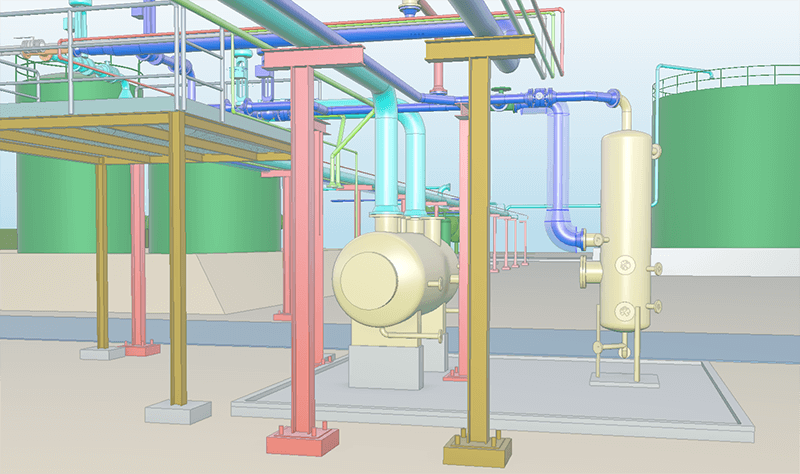

Project designed by ValoSys with CADMATIC Primary.

Vincent has also been impressed with the efficiency gains that ValoSys has achieved with CADMATIC Primary. In this regard, he highlights the ability to copy piping specifications from already-defined projects to other projects.

“After you have copied the specifications you only need to make some modifications to them in the new project, which saves a lot of time. Using parametric equipment is an investment on the first project, but is a real gain after that,” Vincent explains.

He also mentions the ability to review models online with clients and partners in CADMATIC eBrowser. It is convenient for ValoSys that meeting participants can navigate through the model before meetings in order to ask relevant questions or provide new options that can be quickly integrated.

Vincent adds consistency as another key benefit.

“It is very beneficial to know that your isometrics and associated bills of materials will be consistent with the P&ID requirements and with the piping specifications. Basically, you just have to check the visual appearance of the isometric drawing.”

The ValoSys management team from left to right: Technical & Innovation Director Vincent Doucet, Development Director Laurent Debû, and Technical and Commercial Director Hédi Bessibes.

When asked about what the best software features of CADMATIC Primary are, Vincent points to the full set of equipment and instruments that are included in the P&ID application

“This makes it easy to start and you can add as many objects as you want to your own library.”

The consistency check between P&ID and the 3D model is another appreciated feature.

“The consistency check is not too invasive. It is flexible enough to allow you to model differently from what has been defined in the P&ID and to check/correct the most relevant parts. Sometimes you stick to the P&ID and sometimes a smarter arrangement is found in 3D.”

Vincent also indicates that piping layout is easy in CADMATIC Primary.

“The connections to equipment are consistent which avoids mistakes. Once this is done, isometric production is really fast and very little or no touch-up work needs to be done afterwards.”

To conclude, Vincent says that ValoSys has also appreciated the support that Cadmatic provides, not only during the initial installation and training, but also in day-to-day trouble shooting.

Read more about how you can implement powerful plant design tools with the cost-efficient CADMATIC Primary package on a subscription basis with network licensing.

Compact, but hard-hitting

Hungarian oil & gas excellence

Pharmaceutical plant excellence