Customer challenge

- Need to reduce errors during the construction phase.

- Office staff and site workers need to communicate effectively during construction, commissioning, and startup.

STC Power – A leading EPC power plant supplier and Cadmatic user.

Customer challenge

Cadmatic solution

"Using Cadmatic has had a positive effect on our working methods” – Paolo Fantini, Technical Manager

Founded in 1981, STC Power is a leading EPC supplier of waste heat recovery and energy production from conventional and renewable sources. STC Power is specialized in combined heat and power plants based on gas turbine generators and reciprocating engines as well as liquid and solid biomass fuelled power plants. It has extensive experience in combined cycle power plants.

The company is located in Forlì, Italy, where eight years ago, it started working with Cadmatic for the first time. Since then it has successfully completed a wide range of demanding EPC power plant deliveries based on designs created with Cadmatic plant design software.

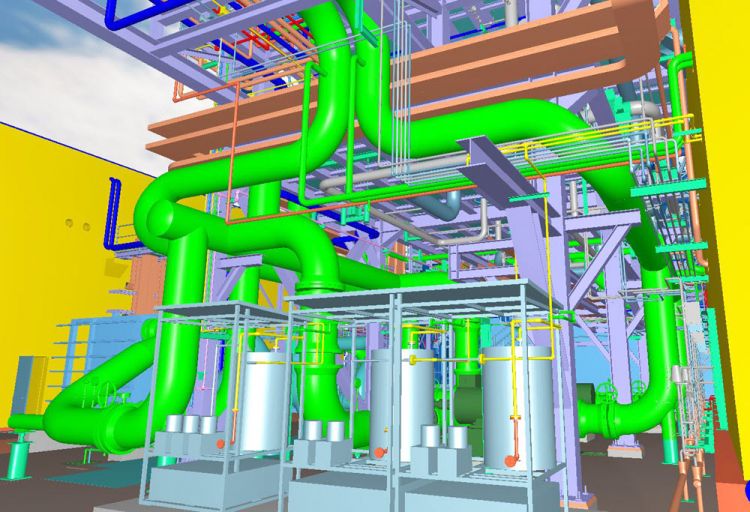

Paolo Fantini, Technical Manager at STC Power, is enthusiastic about Cadmatic. The software was purchased in 2009 for 3D modelling and process and instrumentation (P&I) diagrams to design mechanical parts such as piping, supports and so forth.

“The main reason we started using Cadmatic was to reduce errors during the construction phase by designing with a common database. Using Cadmatic has had a positive effect on our working methods,” says Paolo.

EPC companies require the engineering, procurement and construction process to work as seamlessly as possible. They also need to keep an eye on costs, especially during the erection phase of plants. An area that can be the source of additional costs is modifications that are required at this very late stage of projects. Therefore, investment in professional plant design software is a key issue for success.

According to Paolo, Cadmatic has assisted STC Power in minimizing the need for modifications.

The CADMATIC eBrowser project review tool is also highly appreciated by STC Power office staff and site workers alike.

“By using eBrowser we improve communication between the office and the site, not only during the construction phase, but also during the commissioning and startup”.

STC Power is currently in the commissioning phase of a 15 MWe Enel Green Power Biomass power plant in Italy as well as a 150 MWe IPP GT combined cycle power plant in Israel. Both these power plants are being designed with Cadmatic.

STC Power has shown interest in trialling the CADMATIC Cable Router. The Cable Router has a fully automated routing functionality that selects the optimized routes for cables, calculates their cut lengths and checks cable way fill rates and possible collisions in cable jumps between cable ways.

“We want to test the cable router functionality in the future, but our main objective is to share the model and work with more vendors and customers,” Paolo concludes.

Read more about how your organization can minimize errors and the need for costly modifications with Cadmatic plant design software. See also how CADMATIC eBrowser can improve communication between office staff on site workers during construction, commissioning, and startup.

Swiss precision engineering

GreenE implements Cadmatic for complex waste to energy plant design

Already a CADMATIC user since 2009, NPCIL has increased its number of CADMATIC licenses and upgraded to the latest version.