Customer challenge

- Modifications to existing plant require accurate data. On-site manual measurement is time consuming and prone to error.

Gaining efficiencies with laser scanning technology

Customer challenge

Cadmatic solution

“Accurate laser-scanned information can be imported and used on design projects, which speeds up the entire design process.” – Peder Ögren, Project Department Manager

Smurfit Kappa Piteå in the north of Sweden is the largest producer of kraftliner in Europe, with an annual output of 700,000 tons of base paper used in the manufacturing of high-quality corrugated packaging. In order to bring efficiencies to its plant design and modification projects, the company has invested in a laser scanner and CADMATIC Laser Scan Modeller.

With the help of these tools, Smurfit Kappa Piteå avoids the need for manual measuring at the plant during projects and provides engineering suppliers with more exact and better quality information to be used as the basis of design work.

Smurfit Kappa Piteå’s business relationship with Cadmatic stretches back to 2000, when it purchased eBrowser licenses to review plant models designed with Cadmatic software by consultants. Today, the company hosts its own Cadmatic model and database that covers parts of the plant. Some of the subcontractors also use the Cadmatic's CoDesigner to distribute projects and master replicas.

Smurfit Kappa Piteå’s latest addition to the Cadmatic software ecosystem, the CADMATIC Laser Scan Modeller, was implemented in 2017. It is used in conjunction with a FARO Focus 3D laser scanner, which the company purchased for use by its own staff and those of its engineering subcontractors.

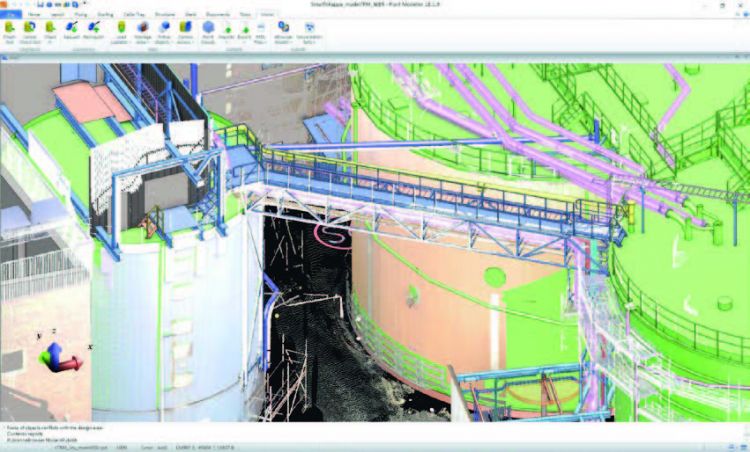

The point clouds produced with the laser scanner can be imported into Cadmatic 3D models to act as a guide when modifications are required. According to Peder Ögren, Project Department Manager at Smurfit Kappa Piteå, the laser scanner and the supporting Cadmatic software have completely changed their way of working, especially in revamps and modification projects.

“We want to avoid losing valuable time in projects with designers running around the plant taking manual measurements. It is not only time consuming, but humans can make errors, while the laser scanner produces measurements that are accurate up to the nearest millimeter. In the worst-case scenario, a human error can lead to operational downtime. Now the accurate laser-scanned information can be imported and used on design projects, which speeds up the entire design process. Any modifications to the design can immediately and reliably be verified in the 3D model for its feasibility. It practically eliminates the need to make any assumptions or do guesswork,” says Ögren.

The FARO laser scanner is also used by some of Smurfit Kappa Piteå’s engineering subcontractors.

“It makes sense for our subcontractors to make use of the laser scanner. This way they can scan precisely those areas they need to work on and import the point clouds for use in the design projects. This also eases the workload on our side so it’s a win-win situation,” Ögren continues.

Smurfit Kappa Piteå follows the design process and reviews designs created by its subcontractors with CADMATIC eBrowser.

“Accurate laser-scanned information can be imported and used on design projects, which speeds up the entire design process.”

“Our subcontractors publish eBrowser models when the need arises. It’s a very easy and efficient way to check the status and make comments on the design as you can see the existing model with the point clouds and current designs all in one place,” says Ögren.

A growing number of Cadmatic companies are showing an interest in laser scanning technologies and the CADMATIC Laser Scan Modeller. Smurfit Kappa Piteå is a good example of how these technologies can be implemented beneficially.

“We are very proud of our association with Smurfit Kappa Piteå and the good working relationship we have built up with them over the years. It is our goal to be associated with the top companies in their respective fields. I am also happy that Smurfit Kappa Piteå has implemented our Laser Scan Modeller successfully and that they are reporting efficiency gains,” says Jim Nyroos, Senior Sales Manager at Cadmatic.

Read more and watch a video about how laser scan modeller can be used to bring efficiencies to revamp and modification design projects.

Gaining efficiencies in constructability and construction project phases

Goes mobile with eGo

Hungarian oil & gas excellence