Customer challenge

- Need to improve pipeline system transparency, particularly when repairs or minor modifications to existing systems are required.

Preventive and predictive maintenance lowers costs while increasing plant safety.

Customer challenge

Cadmatic solution

"eShare speeds up data reconciliation and reduces the possibility of errors due to miscommunication." – Dénes Liktor, Manager Maintenance Capex

BorsodChem, the largest chemical company in Hungary, has been prioritizing plant life cycle analysis for years. It supports the company in monitoring and evaluating the real condition of its devices and equipment, to schedule inspections accurately, and to plan necessary repairing and renewal on time. It improves both the bottom line and enhances plant safety at the same time. In a related investment, BorsodChem has implemented Cadmatic’s eShare digital twin solution in May 2022 at some production plants to boost data visualization and integration.

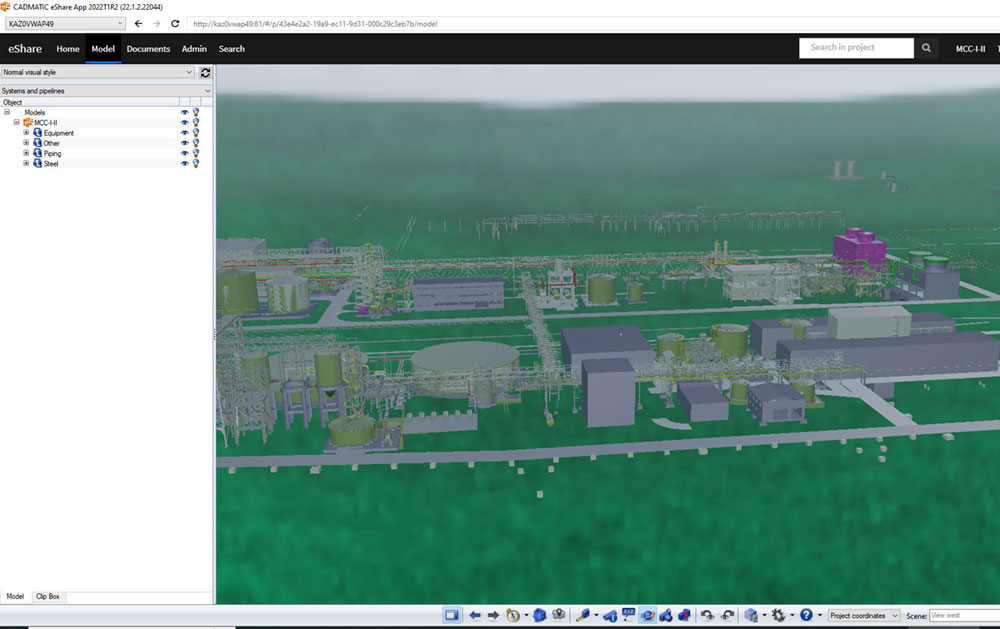

BorsodChem is one of the Europe's leading producers of plastic raw materials and inorganic chemicals. Its Kazincbarcika site is one of Europe's largest manufacturers of MDI, TDI, PVC resin, and chlor-alkali chemicals. BorsodChem has been part of the Wanhua Chemical Group, a global supplier of chemical innovative products headquartered in China, since 2011.

According to Dénes Liktor, Director EHS (until the end of 2022 Manager Maintenance Capex) at BorsodChem, their maintenance activities have been improving for years and have become much more predictive and proactive in recent years.

It is confirmed by the fact that plant - equipment life cycle analysis has also recently become a major focus for BorsodChem.

“We are performing increasingly complex and in-depth tests on key devices during periodic inspections, which allows us to get a complete and accurate picture of their condition. This enables us to be more proactive in scheduling future inspections and planning for necessary refurbishments and replacements as the devices reach the end of their operational lifespans. This is critical for the company in terms of both safety and cost," says Dénes.

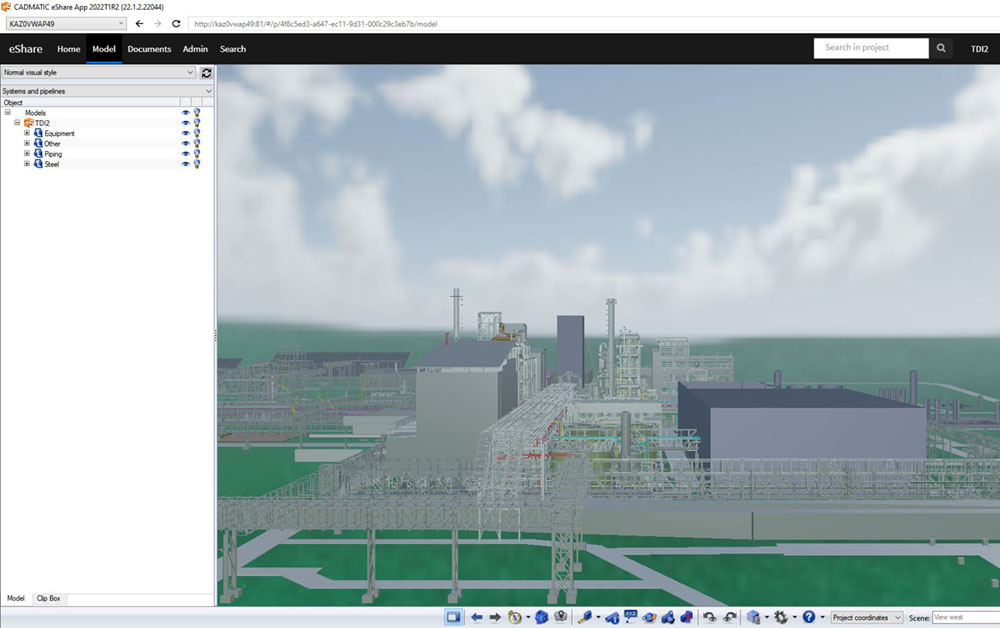

BorsodChem acquired 60 CADMATIC eShare licenses for use at Kazincbarcika site in May 2022, following a thorough evaluation period. More plants have integrated the digital twin platform with nine of the plant's operational systems. The first of these integrations is currently underway with the SAP ERP S4/Hana system with others to follow.

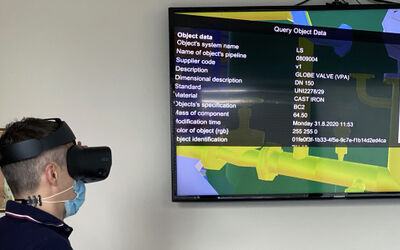

eShare was implemented for pipeline system visualization to improve pipeline system transparency, particularly when repairs or minor modifications to existing systems are required. Dénes says that it saves time and provides more clarity during repairs and maintenance.

"eShare also aids us in planning the installation and removal of larger devices. In these situations, it is critical to visualize the required route and identify bottleneck profiles. In the 3D environment, we can easily identify critical points, double-check installation plans, and detect errors early," Dénes says.

He also mentions that eShare helps them with data reconciliation with external designers.

"When we work with external designers and companies, eShare speeds up data reconciliation and reduces the possibility of errors due to miscommunication."

Dénes summarizes the main advantages of eShare as follows:

With these advantages in mind, Dénes adds that they intend integrating more devices for monitoring and projects where eShare can be of assistance.

Zoltan Igaz, Senior Sales Executive at Cadmatic is delighted with how much BorsodChem has gained from eShare.

"Chemical plants are extremely complex, so staying on top of things is critical. I like BorsodChem's vision of bringing data from various systems together and visualizing all the data on a single platform. This means they don’t have to worry about data silos while they still maintain control over data security," says Zoltan.

Postscript: From 1 January 2023, Dénes Liktor has continued focusing on eShare as Director EHS, assessing its benefits from a safety perspective.

Developing integrated design projects with Cadmatic

CADMATIC eShare implemented in Helen Ltd heat pump project.