Customer challenge

- Need for practical and cost-efficient design solution that comes with fast support to reduce time required to solve possible software management problems.

Swiss precision engineering

Customer challenge

Cadmatic solution

“Cadmatic helps us to reduce data loss and achieve better quality end products" – Camillo Martiradonna, General Manager

Headquartered in the southernmost part of Switzerland in Mendrisio near the Italian border, Alba E&C (Alba) is ideally located to serve a wide range of European industries. Part of the company’s philosophy is integrating its engineering services with the most innovative data processing technologies available.

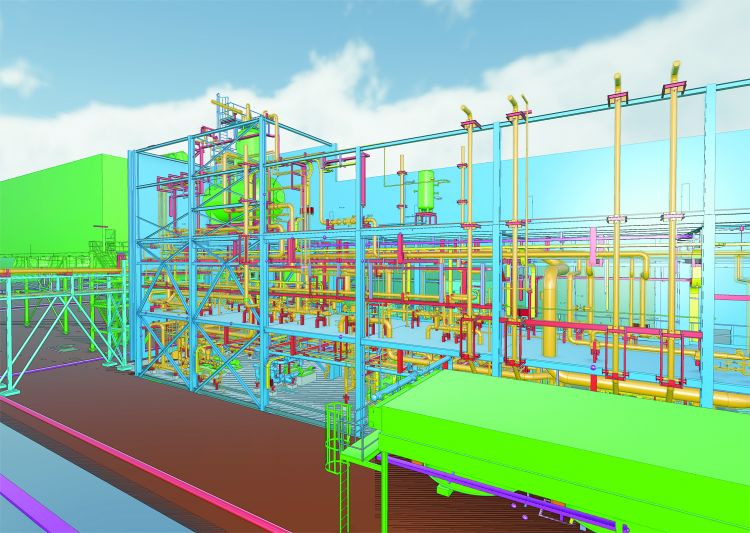

In 2016, Alba implemented Cadmatic, which it now uses for design and information management purposes. Not shy of challenges, Alba has already used Cadmatic for the design of a wide range of demanding industrial plants.

Alba was founded in 2008 as a trading company in the steel industry, after which it evolved into an engineering company specialized in the design of industrial and civil plants. Since its remarkable transformation, the company has been supporting its customers in all design phases. Alba’s multidisciplinary skillset covers a wide range of engineering disciplines, as well as software development.

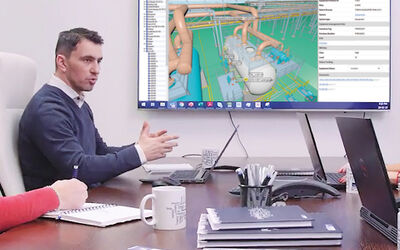

General Manager Camillo Martiradonna has been with Alba since 2011. He was instrumental in overseeing the evolution at Alba from a steel trading company into one that specializes in piping and civil engineering.

“Cadmatic helps us to reduce data loss and achieve better quality end products. We set up the electrical, instrumentation and control departments first in 2014, which was followed by the process and automation departments in 2016. From our new head office in Mendrisio, we are able to support clients in basic and detailed engineering, job management and material procurement,” explains Martiradonna.

In 2016, after many years of using various 3D modeling software packages, Alba were keen to implement a practical and cost-efficient solution. According to Martiradonna, a key requirement was real and fast assistance to reduce the time required to solve possible software management problems.

“After testing the software in 2016, we decided that Cadmatic would be the ideal solution for us. Today we have trained all the staff to manage and complete multidisciplinary design tasks. Our IT team was impressed with how user friendly the software administration is. It also takes less time to train new users in Cadmatic than with other software,” says Martiradonna.

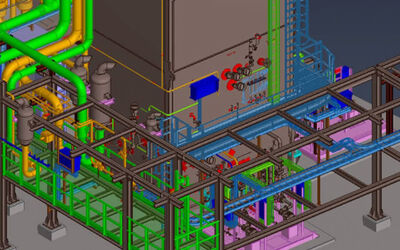

A recent challenging project by ALBA with Cadmatic was the design of a thermoelectric power plant for Termokimik Corporation Impianti E Procedimenti Industriali Spa in Russi near Ravenna, Italy. The plant covers an area of 230 square meters and produces 40 MW of electrical power with a steam turbine. The steam necessary for the turbine is produced in a combustion thermal cycle with wood chips. The turbine has five spindles in the Rankine cycle.

When asked about which software features he particularly appreciates, Martiradonna mentions the relative ease with which 2D documentation necessary for the procurement of materials, prefabrication and construction can be extracted. Cadmatic’s automatic cable routing feature and information management tools have also impressed him.

“With the latest release, the automatic cable routing module can save a lot of time in engineering. Our management team uses eBrowser and eShare to ease communication between designers and managers. This ensures that we have less data loss and achieve better quality end products.”

Read more about how Cadmatic plant design and information management solutions can boost efficiency and quality in your organization too.

Boosting information management with CADMATIC eShare and eGo

SIAD gains efficiency with Cadmatic plant design software.

Pharmaceutical plant excellence