Owners and Operators

P&I Software solutionsCADMATIC Plant Software Solutions can be used in all phases of the asset life cycle: conceptual design, FEED, detail design, procurement, construction & commissioning, operations & maintenance, decommissioning and revamping.

Our state-of-the-art information management solution forms the platform for digital twins of industrial plants and optimizes asset management throughout the entire life cycles of industrial plants.

Data-driven engineering and asset management

Data-driven engineering and asset management are core values embedded in all CADMATIC products. Our products ensure optimal use of all digital data throughout entire asset lifecycle: from the initial 3D models and legacy data converted from other formats or captured with 3D laser scanning up to a platform for hosting digital twins. Digital data generated at every stage of asset management is handled effectively and presented to the user in a way that to supports numerous operational needs.

Unleash the power of digital twins

The 3D model is a core element of the digital twin of your industrial plant. All data is instantly available for asset life-cycle management: design data, as-built data, 3D captured scans and comments with photos, and operational data are integrated into a single digital environment. Data handling is minimized, and the latest information is digitally and readily available for design, construction, and operation and maintenance personnel.

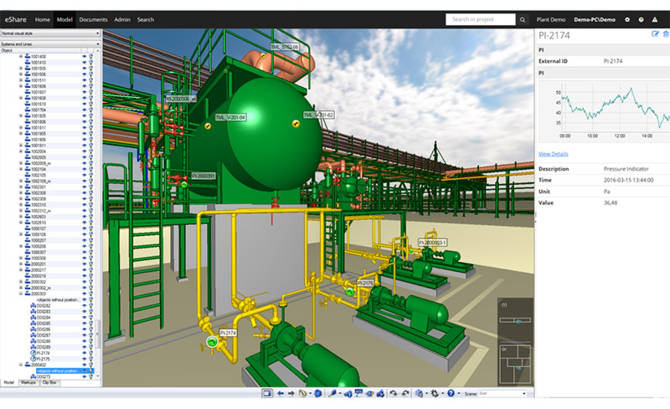

The CADMATIC eShare solution functions as the platform of the digital twin. It can be integrated, for example, with preventive maintenance management, risk analysis, and process analysis software.

eShare is fully compatible with Intergraph, AVEVA, Plant3D, IFC, DWG, DGN and other 3D and 2D formats, making it possible to combine legacy data and all project data in a single access point.

A variety of customers from different industries use CADMATIC. See our references for application in operations, engineering, procurement, and construction project phases.

Revamping and engineering

CADMATIC’s efficient design tools and integration with laser-scanned point clouds make for the ideal combination to complete revamp design projects efficiently and within budget.

Using point clouds as a design reference in the 3D model allows more significant prefabrication of process parts and ensures that process elements fit perfectly. It shortens the design process, improves quality and reduces production downtimes significantly.

Read more about the use of CADMATIC products for EPC-type projects

Read more about use cases of eShare for Owners and Operators.