Customer challenge

- Ensure all project stakeholders have access to the latest versions of models and documents

- Integrate extensive laser scans with project models efficiently

Customer challenge

Cadmatic solution

“We were able to showcase the features of eShare on the WSF pilot project in less than two days” – Nathan Larsen, Senior Marine Designer

Celebrating over 65 years of service in the marine industry, the full-service naval architecture and marine engineering company Glosten recently embarked on a groundbreaking pilot project that involved the retrofit conversion of the three largest Washington State Ferries (WSF) into plug-in hybrid vessels. The project not only signifies a leap towards sustainability but also showcases CADMATIC eShare as a powerful tool to track shipyard work.

Based in Seattle, Washington and Providence, Rhode Island, Glosten specializes in vessel design and modification, marine operations and logistics, marine offshore structures, vessel procurement consulting, technology development, and marine infrastructure.

According to Nathan Larsen, senior marine designer at Glosten, the team had eyed eShare for several years, awaiting the perfect project and client opportunity. That opportunity presented itself when Glosten began working with Siemens Energy and Washington State Ferries (WSF).

To achieve zero fleet emissions, Washington State Ferries (WSF) is moving towards converting their three largest ferries to plug-in hybrid-electric propulsion. Glosten’s work on the project involved extensive laser scans of the vessels, modeling new equipment, and creating production deliverables.

The Glosten team needed a solution to track shipyard work on the project, and Nathan indicates that eShare seemed like “the perfect fit.”

“After discussions with Cadmatic, we were able to run a demo environment from the model overnight. After a short meeting to align naming conventions, the team was able to link drawings the next day. This allowed us to showcase the eShare features on the WSF project in less than two days.”

WSF M/V Wenatchee Dockside for hybrid conversion

One of the challenges Glosten has faced on large projects in the past is ensuring all team members access the latest model and deliverable version. Nathan indicates that with eShare, they host a website through which clients can access the latest model file and drawing deliverables without requiring separate licensing or software.

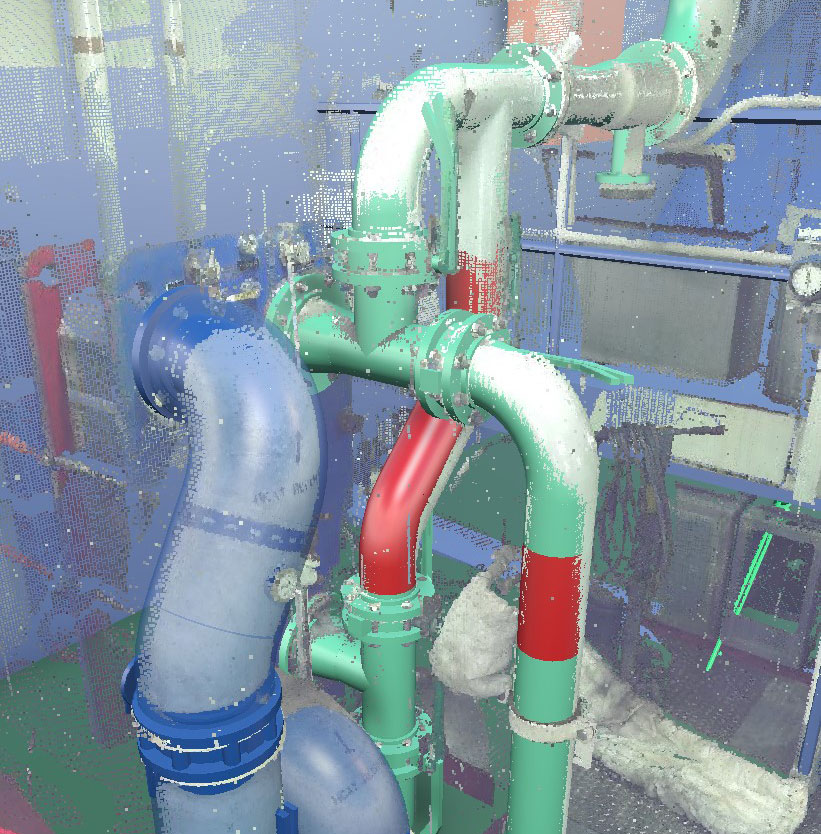

“The ability to integrate point clouds in eShare also eliminates the need to send several gigabytes of point cloud files to each person that wants to use them. Instead, users can simply turn the point clouds on or off in eShare,” Nathan explains.

Sample eShare model image with point cloud overlayed

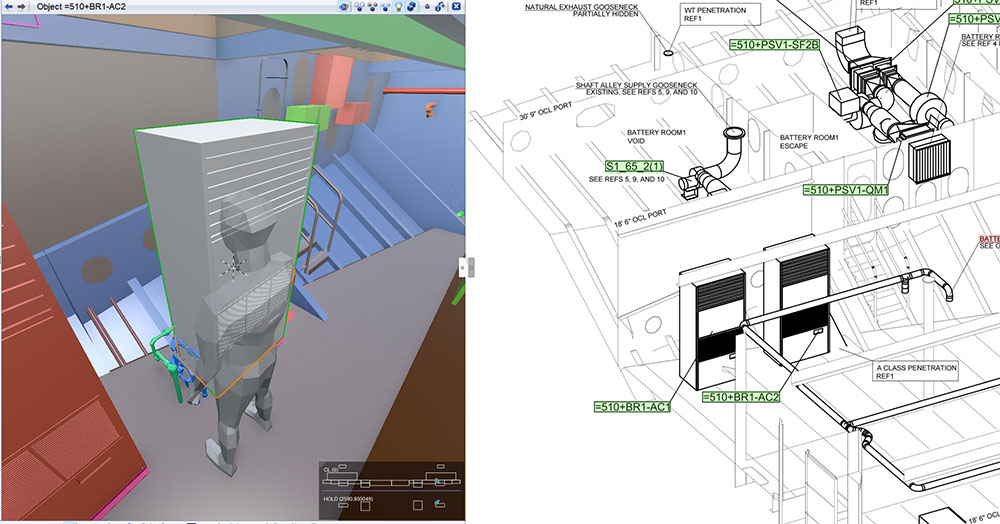

Another challenge arises when project stakeholders, who may be unfamiliar with Glosten’s deliverables, want to review the 3D model related to something they see in a drawing (or vice-versa). This can be particularly time consuming, especially in the case of WSF's ferries: double-ended vessels with much of the same equipment on both ends.

“eShare’s ability to link equipment in drawings to objects in models directly resolves this problem, which in turn saves time spent searching models for an object, prevents confusion, and reduces errors,” says Nathan.

He adds that similar features they have encountered in the past required lengthy setup time, but that the process was extremely fast with eShare.

“Our team was building links in the demo environment within minutes. We've now routed hundreds of cables from multiple vendors for the WSF project, and the integration of links to all relevant drawings for any given cable is incredibly helpful for quality assurance and installation.”

Many cables that originate from different vendors have slightly different naming conventions and drawing types, but according to Nathan, eShare handles this easily.

“As long as the PDF drawings are searchable, eShare can quickly create links to corresponding model objects and save us the effort of doing it manually. In addition to linking our production drawings, diagrams, and electrical drawings, we have also linked cable diagrams from vendors and structural drawings from sub-consultants. This puts us in an ideal position to collect and manage project data to support the success of the project, rather than limiting the impact to our own scope,” Nathan explains.

eShare's new sidebyside feature showing the drawing and the model with links between the two

As the first vessel moves to the shipyard, Glosten plans to implement an additional feature which enables tracking the installation status of equipment on the vessel and report progress.

"The client can walk through the vessel with a tablet, mark what equipment has been installed, and quickly run a report to Excel to track the installation status," says Nathan.

This feature can also be used on cables, pipe spools, and other model objects, making it easier to track what has been built and what has not.

“This allows us to quickly change a model's color-coding to show what has been and still needs to be installed in a particular space,” says Nathan.

Since this is a three-vessel conversion project, Glosten also plans to take advantage of mark-ups in eShare. Mark-ups allow users to make notes and include pictures of what was built in the model. This helps ensure that the appropriate changes are also made on future vessels. Mark-ups also allow statuses to be tracked and specific users to be assigned for follow-up.

Senior marine designer Nathan Larsen checking and comparing the new seawater overboard in CADMATIC eShare.

Glosten's leadership was delighted with the speed and ease of the eShare setup, which allowed Glosten to quickly show the client all the eShare features using their project instead of a demo.

"The ability to overlay point clouds on Navisworks and eBrowser models that are always up to date will be a time saver, ensuring all parties see the same model," Nathan adds.

Glosten plans to roll out eShare for new projects going forward.

"We are only starting to scratch the surface of the platform's many capabilities, and with the right shipyard partners we can fully leverage eShare for both new build and retrofit work."

This successful pilot project with CADMATIC eShare is a testament to Glosten's innovative approach in the marine industry and paves the way for future collaboration.

Read more about Cadmatic ship design solutions.