See how you can quickly create a block of a ship from scratch with CADMATIC Hull

Albwardy Damen gains efficiencies from digital transformation

Implements CADMATIC eShare to visualize production processes

Albwardy Damen is a leading provider of shipbuilding and ship repair services in the marine, and oil and gas-related industries in the Middle East. The joint venture between Albwardy Investment, Dubai and the Damen Shipyards Group employs about 1,300 people in three locations in the UAE: Dubai, Sharjah, and Fujairah. A recent accolade for the shipyard was being recognized as the Best New Building Yard at the 14th edition of the ShipTek International Awards 2021, held in Dusit Thani Hotel, Dubai, on June 7, 2021.

In May 2022, the shipyard implemented the CADMATIC eShare information management platform to visualize production processes.

According to Arun Sidharthan Lead Engineer at Albwardy Damen, their management became interested in eShare after seeing a demo given by the Cadmatic Middle East office.

"We immediately thought that eShare could be used to highlight production progress statuses in different colors. After the training and implementation, we now see a role for it also in accessing production drawings, sending markups (comments in 3D model), checking material availability statuses, ETA details for equipment and purchased items, automatic progress updates from our ERP system and pipe shop digitalization”.

Easing the work of production supervisors

One of the key benefits of eShare for Damen Albwardy is that it eases the work of production supervisors. It does this by connecting all project-related documents and data from different databases in a single platform.

The engineering team indicates that traditionally production supervisors used four to five computers located near vessels to access project drawings. They needed to navigate to multiple folders to open or refer to the required drawings and carry difficult-to-manage A1 printouts on board. They also needed to log in to the ERP system to check material availability and the yard’s digitalization platform to check spool production progress.

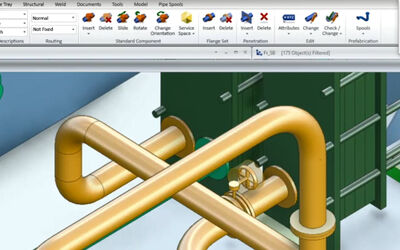

“With eShare, the production supervisors can use touchscreen tablets to access production drawings, spool and ISO drawings, project planning and the building strategy. eShare is also linked to our ERP system so all the required information contained in drawings and details about purchasing and project progress are available with a single click. This is very useful and saves time.”

The Albwardy Damen Engineering Team during training and implementation.

Visualizing real-time progress reports to identify bottlenecks

Albwardy Damen’s production team can use color coding in eShare to visualize which items are fitted or not ahead of key construction milestones such as closing shell plates or turning blocks. The color-coded visualization assists them to easily identify which items are not fitted, after which the necessary actions can be taken.

“In the past, we used to refer to various progress reports and feedback from supervisors to identify such cases, but now we can get the details directly from eShare."

Keeping clients in the loop

End clients can also view the visual progress from their locations or send their comments in eShare. This is another area where eShare is being put to work at Albwardy Damen.

“Our project managers can open the eShare model and visualize the real-time fabrication/fitting progress of the hull, foundations, and pipe spools with different colors. They can also see the installation progress of valves and equipment. This information can be shared with clients from eShare or used in meetings.”

Easing communication between engineering and production

A common headache for production supervisors is keeping track of issues and statuses when communicating with engineering. In a traditional setup, this means sending emails with questions and queries to the engineering department, who then reply via email or update drawings accordingly.

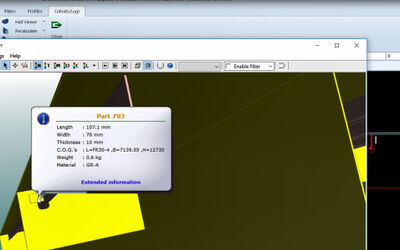

eShare eases this process considerably as production supervisors can comment directly in the 3D model via markups to send the queries and clarifications and assign them to a dedicated person.

“We created markup types for each group and customized the excel markup reports with status and other columns as per our requirements. This makes it easier to handle all the production queries and keep track of all the points to implement for the same kinds of projects in the future.”

Read more about Cadmatic solutions

Read more about CADMATIC eShare and other information management solutions.