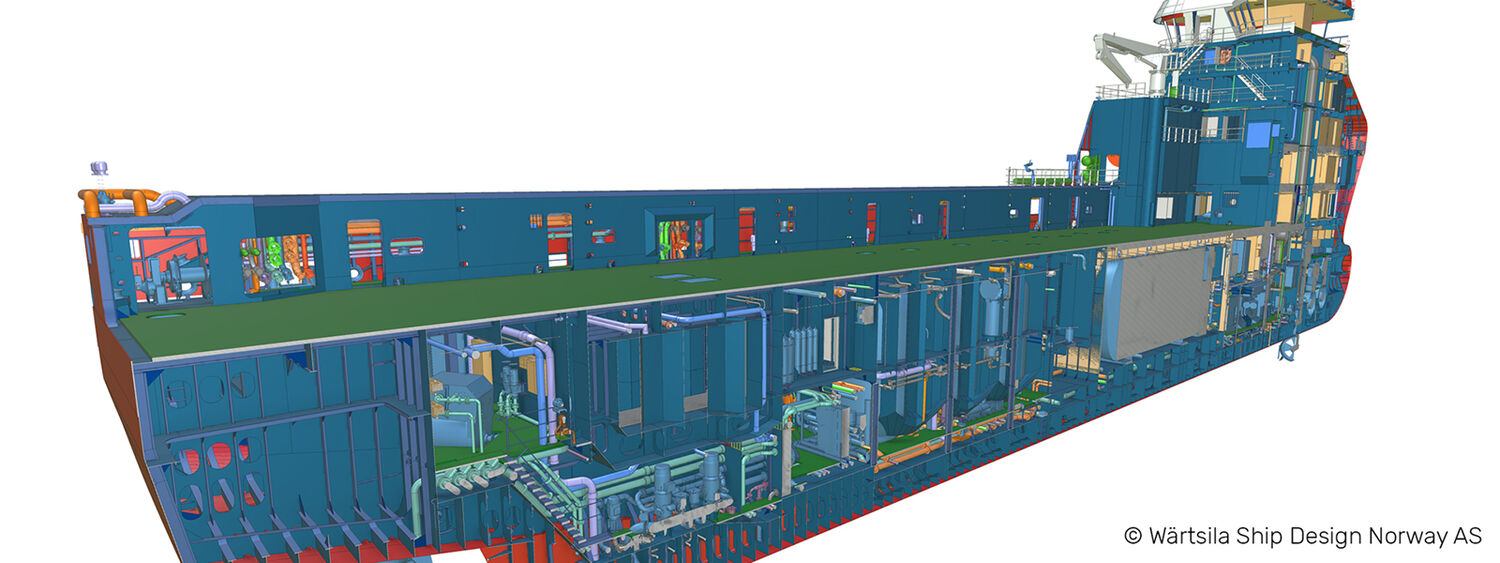

Detail Design and Production Information

CADMATIC's software for Detailed Design and Production information - data-driven approach for ship design and shipbuilding

With open, flexible, customizable and user-friendly attributes, CADMATIC ensures that the detail design phase is completed in the shortest time possible with the best quality designs. The intelligent and intuitive functionalities ensure that the models are accurately and efficiently designed and engineered. The topological data consists of relations between parts, which means that if a part is modified, the related parts change as well. This allows changes to be made easily and saves a lot of time during modifications.

CADMATIC contains a comprehensive hole manager, advanced weld managers and automatic bevel creation. The highly accurate shell plate development calculations include the creation of production templates and take the elongation data of plates into account. This prevents extra work during the build and ensures that all parts are delivered to the yard correctly.

Production information is generated automatically for part manufacture and assembly and 2D drawings are updated when changes are made in the model. With our sophisticated clash checks in the 3D model, we ensure error-free models and drawings for installation and production. It is always easier to solve these issues in the office while modelling than to deal with equipment and steel parts that have been delivered in the wrong sizes.

Production data can be fed directly into cutting, bending and welding machines to speed up production. CADMATIC offers yards a work-breakdown manager to sketch a build strategy to save even more man-hours. This empowers the yard to start building the moment the data is extracted from CADMATIC.

Products for Design and Engineering