Data that fuels shipbuilding – the role of CAD/CAM in data-driven shipbuilding

Written by Ludmila Seppälä

Posted on January 18, 2021

Shipbuilding has a rich history that spans centuries. Traditionally, it is considered an industry that requires a lot of intelligence and science. Vessel design requires extensive knowledge about stability, shapes, structural strength, engines, equipment, materials strength, and much more.

Modern ships are complicated autonomous floating storages and transporters, power generators, refineries, living quarters, and leisure facilities. It takes years to design and construct modern vessels: the joint effort and coordination of numerous designers and engineers, meticulously organized work in materials and equipment procurement, assembly lines, workshop floors, and shipyard process management. Months of testing and adjustments are needed to ensure operational stability, train the crew, and set up maintenance schedules.

Shipbuilding as a data flow process

Looking at the shipbuilding process from a data flow perspective is fascinating. From concept and basic design up to the shop floor and operations – a massive amount of data is created and used for various needs. Calculations performed for stability and flotation are critical in the initial stages, but not needed in production. Planning of production and work breakdown sequences can be prepared after the detailed 3D model is complete. The grouping of engineering, design, procurement, and production processes is non-linear and often simultaneous; the same can be said about data flows.

One might think that CAD/CAM/CAE packages take care of the whole cycle from the beginning of the project to the very end. However, a closer look reveals that shipbuilding's digitalization process is fragmented and often too narrowly focused. There are many types of data that originate and evolve during the shipbuilding process: engineering and calculations, 3D geometrical and meta-data, logistical sequencing, work breakdown information, and production data generated according to specific machinery needs.

Shipbuilding’s intense design focus and use of AI

The shipbuilding industry is distinctively different from other industrial sectors due to the intense focus on design. The so-called CAD-centric approach emphasizes the 3D model and its role in shipbuilding as the single source of truth.

The other significant trend is the use of AI and machine learning technologies. Machine learning mechanisms can assist in design decisions made by engineers and naval architects. Regulations and best practices are embedded in CAD/CAM systems to help and act as a reliable knowledge storing facility. This process is not novel, as the first specification-driven features date back to the origin of CAD/CAM systems. However, new technologies such as neural networks and algorithms for the use of big data have opened up new possibilities.

It is true that for shipbuilding, the 3D model and related documentation extracted from it constitute a foundation. However, this leaves the shipyard processes uncovered. As a result, a functional gap was created between design data and the PLM/PDM/ERP needs to manage the shipyard operations.

Digital twins are the hub of ship information model

A common trend in modern CAD solutions is to look beyond creating the 3D model and extraction of production information. Incremental digital twin creation places the 3D model as the hub of the information model, adding layers of integrated non-centralized data. Essentially, this can be any data from any system that has an application in the shipbuilding process.

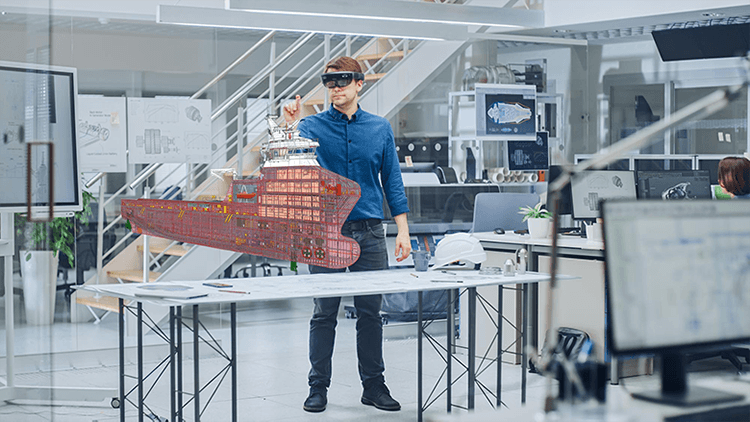

This approach aims to resolve the information gap and directly link the design and PLM-related data. The role of the CAD/CAM solution changes – instead of a tool for engineering and design, it takes on a universal 3D dashboard position. Adding information on top of the 3D model resolves the linking of data and information perception. Instead of looking through datasheets, users can see a 3D rendering of the end model and manipulate the data on a 3D dashboard. Advancements in computing power and new technologies take this even further – the data is available in any format and on any device – up to life-sized holograms in physical locations with AR/VR/MR/XR technologies and wearable devices.

The future development of CAD/CAD trends emphasizes the role of digital information flows and the process of digital twin creation. However, for the time being, it remains focused on the end product of a shipyard, a vessel that is delivered to the shipowner.

The next gap in the digitalization process is between shipbuilding data and operation, maintenance, and shipping. Creating specialized digital twins for each stage of the vessel's life cycle, seems to be a cumbersome and ineffective approach. Developing and facilitating a universal digital twin requires a broader perspective on digitalization and data flows, in which the interests of shipyards and shipowners are aligned.

This article was first published in the January 2021 edition of the Naval Architect RINA magazine