Too busy for smart engineering? – Cadmatic is challenging old ways of working

Posted on December 21, 2021

Enter information into CAD software just once to save time and money. You’ll also reduce the risk of human error. Software features vary, and finding the perfect fit for one’s work will boost efficiency significantly. The change is surprisingly easy to carry out, promise Sami Koponen and Jyrki Metsola of Cadmatic.

Sticking with familiar ways of working and software is often a matter or convenience or due to fearing renewal costs.

“While BIM is in focus in industry, many companies use the same CAD software they have been drawing with for 15 years. Unfortunately, line drawing or ‘unintelligent’ 3D models do not suffice when BIM becomes the standard requirement nor when digital twins become the norm,” says Jyrki Metsola, Vice President, Construction at Cadmatic.

It may be challenging to find time amongst one’s daily tasks to move on to a new way of working and smarter design.

“When people are busy at work, there is no time to make changes. Then, during a quieter season, all investments are postponed. However, a transition usually pays off as the new way of working will increase efficiency and improve quality while saving time and money.”

Doing away with manual information management

Modern design software can “help” the designer with routine tasks so that there is more time to tackle the most demanding tasks. Software can, for example, choose materials and components based on flow specifications so that the piping designer can focus on creating optimal routing.

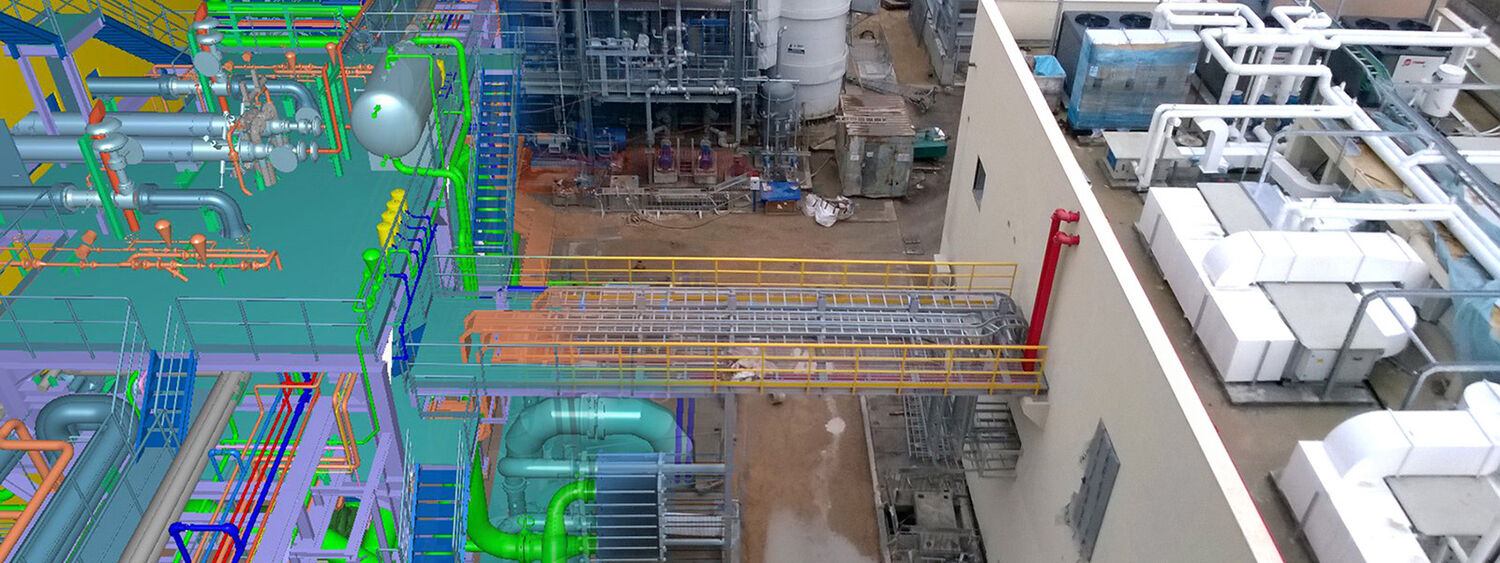

“Once all design disciplines are included in one system, it is easy to exchange information between them. The users do not need to transfer information specifically; they only need to do it once, after which the information is available everywhere it is needed: in documents, reports, and systems integrated with the design systems. Thereby, the risk of manual error is minimized,” Vice President, Process & Industry at Cadmatic, Sami Koponen.

“Cadmatic Electrical is used in industrial electrical and automation engineering. It centralizes all design data in one place while making it available for hundreds of occurrences. In electrical automation, a single project can involve a huge number of documents, and Cadmatic Electrical makes managing and updating them much easier,” says Jyrki Metsola.

Once all design disciplines are included in one system, it is easy to exchange information between them. Thereby users don’t need to transfer information and the risk of manual error is minimized, says Vice President, Process & Industry at Cadmatic, Sami Koponen.

“The best features in the world for distributing work”

The right software also enables distributing work.

“A plant design project, for example, may involve a large number of designers physically located in different places and employed by different companies. In such projects, it is vital that those working on the project are able to use the same up-to-date design information. I think that the Cadmatic plant design software has the best features in the world for distributing work,” Koponen says.

Many companies are using the same CAD software they have been drawing lines with for 15 years. This will not suffice when BIM becomes the standard requirement, says Jyrki Metsola, Vice President for Construction at Cadmatic.

Effortless implementation

The implementation of new Cadmatic software is surprisingly easy and quick to manage.

“Implementation time is on a completely new level compared to, say, five years ago. During the past three years, we have been able to shave off 50% from the implementation time of our plant design system. Organic product development has played a role here as have modern digital solutions,” Koponen says.

Our Cadmatic Academy with self-learning materials helps new users to get started and provides continuous support to designers in their daily engineering tasks. Friendly customer service plus easy-to-access product support are key in solving potential problems in practice.

“We are a Finnish company able to support our Finnish customers in their own language, which is not a given in this business,” Koponen notes.

“Functioning product and service are key”

Cadmatic design software is used in Finland as well as around the world in diverse projects related to construction, the process industries and ship building. Over the years, the company has proved that the choice of a good software vendor is not dependent on their size but their level of service and software quality.

“We have provided software for an office of just a few persons as well as for major international companies. Our software products have helped successfully design projects from very small facilities to very large plant systems. In that, functioning products and friendly service have always been key,” says Sami Koponen.

The largest CAD software provider in Finland

Cadmatic software is developed in close cooperation with our customers.

“We are the largest Finnish CAD software provider, so we have plenty of capacity to develop our software products and customer service to match. The key concepts being developed to create added value for our customers are data-driven engineering and digital twins,” Koponen says.

“Cadmatic Building is the only software on the market to apply BIM automatically based on familiar, effective 2D design. The distance is short from BIM to digital twins that keep developing during design, construction and maintenance. At Cadmatic, digital twins are already commonplace,” Metsola says.

Read more about Cadmatic's flexible licensing, distributed design and data-driven engineering.