Integrating electrical design with 3D modeling improves the bottom line

It is still rather commonplace for some shipyards to consider electrical design as an add-on to main design disciplines such as structural hull and outfitting design. As such, it is often outsourced and completed in its own silo separately from the rest of the ship design project. Shipyards can significantly improve efficiency by integrating electrical design with the rest of their ship design. This may require integrating work from subcontractors and demands a clear understanding of which party takes charge of which task, but it’s worth the effort.

Currently, many shipyards have learned to live with a bearable level of inefficiency when it comes to how electrical design is handled in ship design projects. This often comes in the form of a lack of information from suppliers and the inability to follow project progress and manage changes efficiently. Changes from electrical subcontractors often come unexpectedly and at the last minute, which then requires more changes to the ship design.

It is no small matter, however, when your electrical designer informs you that you, for example, need to make more space for 25 additional electrical cabinets on a design that is already tight. Depending on the scope of changes required, it can even affect delivery in the worst-case scenario. Ideally, this should be avoided with a design approach that integrates all disciplines, including electrical design, from the very beginning of a ship design project.

As ship design and shipbuilding have evolved, we have seen increasing amounts of such integration between different design phases and disciplines. So far, electrical design has been left mainly out in the cold, largely due to its 2D roots and the fact that external turnkey suppliers or subcontractors have traditionally handled electrical design separately

Integrated design approach has great benefits

It makes sense to include electrical design as part of an integrated design approach, however, and the benefits are enormous. Shipyards should expect more from their electrical design suppliers in this regard.

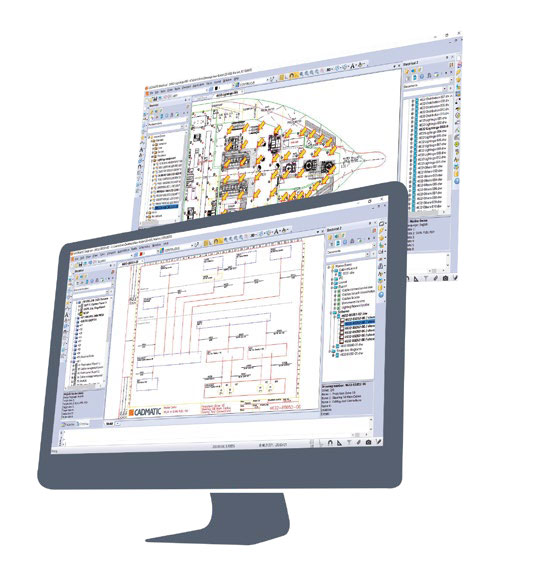

Electrical documents such as schematics, diagrams, arrangement drawings, electrical equipment, switchboards, and cabinets can all be linked to the 3D model. There is also scope to link manufacturing information, supplier data and PLM/PDM/ERP data. With this approach, the project documents and information are always up to date and synchronized with 3D models, which eliminates the need to do time-consuming and error-prone manual checks.

An integrated approach ensures that the design project remains under control without any last-minute surprises and delays. It also improves quality by eliminating human error associated with the manual updating of documentation and models when design changes are made. In short, it improves the bottom line.

CADMATIC Electrical differentiates itself from competitors by offering electrical design that is integrated with 3D modeling.

Start a free CADMATIC Electrical trial