Take a leap forward with data-driven construction

Digital twins drive the digital transformation of engineering, procurement and construction activities and enables EPC companies to develop and improve processes

Posted on July 01, 2021

CADMATIC’s Digital Twin solution for process industry acts as a project collaboration and information sharing portal, including engineering data, scheduling and construction site management. Having the project’s digital information available and visible in one system creates added value and allows more efficient performance for EPC companies during the various project phases.

Digital Twin

Let’s start with digital twins, what are they? A term that is often used is BIM (Building Information Modeling), a process where attribute-information-rich 3D models are created and information attached to objects, is developed during the progress of the project for various needs, including purchasing, construction, and project management.

There are different digital twins for different uses. To put it simply, a digital twin is a virtual representation of a physical object or asset, a bridge between the physical and the digital world. The more data and details are included in the digital version of a physical asset, i.e. the digital twin, the more accurate and reliable is the physical asset connected to it, and it can be used and managed digitally through its entire lifecycle.

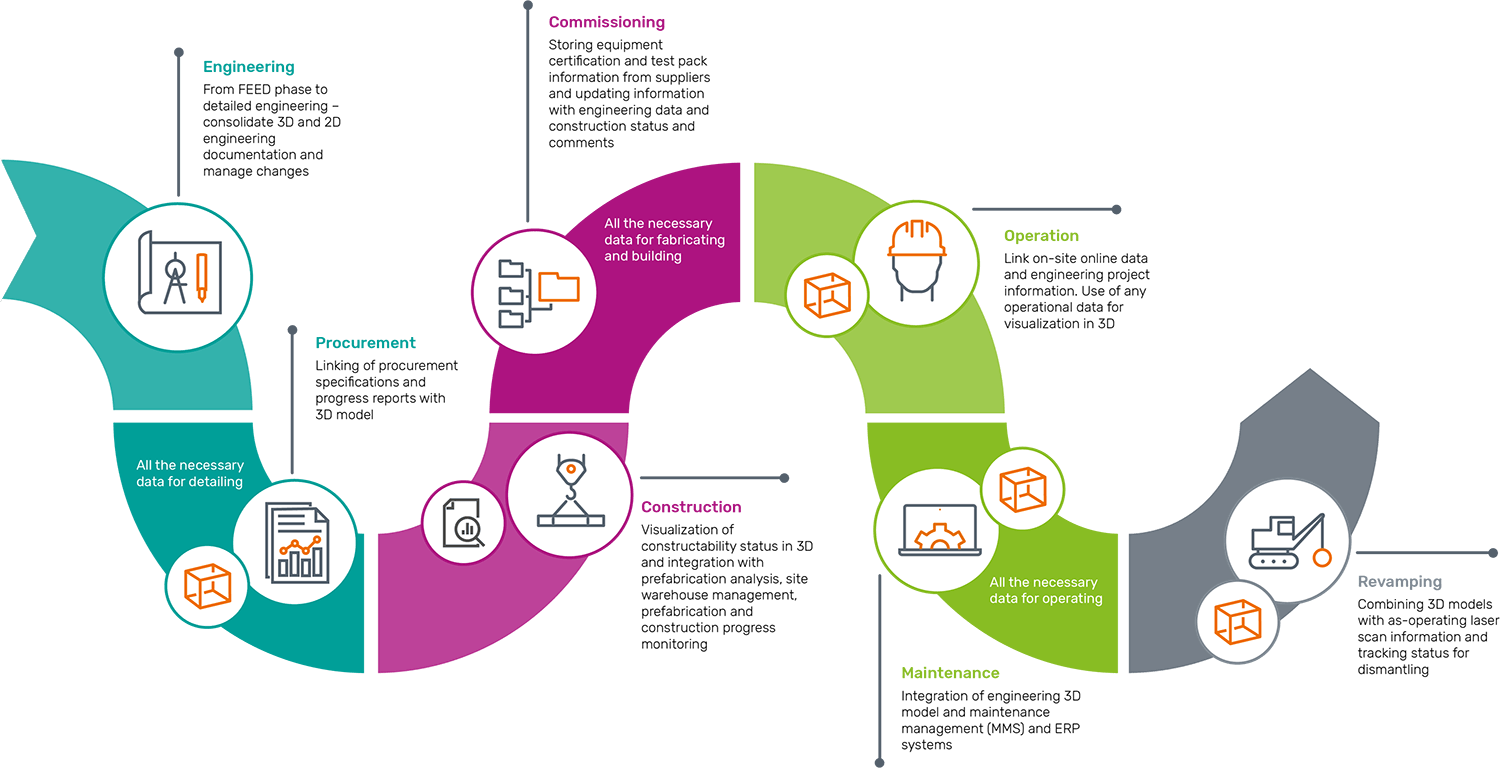

From an EPC company’s perspective, digital twins drive the digital transformation of engineering, procurement and construction activities and enable EPC companies to develop the processes they have in place. In practice, we can define three different phases for the digital-twin life cycle: digital twin for engineering, digital twin for construction, and digital twin for operations. Decommissioning may be considered its own phase, too, but we think it is included in the operations phase.

For EPC companies, the first two phases are obviously the most important, since they are their core activities that involve major annual investments. Taking advantage of digitalization in any which way, including better team collaboration, faster decision-making, more efficient and accurate construction site management – this offers a great opportunity for cost savings and consequently improved project margins.

Data quality and interconnectivity are key factors in boosting profitability

Information needs to be easily accessible and based on quality data. Data quality, consistency, and interconnectivity, as well as maximized automation of data handling throughout the investment’s project lifecycle, are key factors in unlocking greater efficiency, increasing productivity and boosting profitability. When minimizing manual operations, personal competence becomes less critical and is supported by the software.

International oil & gas general contractor Bonatti acquired CADMATIC’s eShare information management system in early 2018 to boost the efficiency of its constructability and construction project phases. Construction Methodologies and Systems Manager Massimiliano Del Rio and Construction Methodologies and Systems Senior Engineer Giovanni Silluzio have been key persons in the implementation of eShare at Bonatti.

An important goal with eShare at Bonatti is to provide support to the construction site in managing and tracking specific activities. One such activity is workface planning, a process aimed at improving the productivity of the construction workforce by removing execution constraints. It ensures that the required installation inputs, such as drawings, materials, procedures, permits and equipment, have been monitored and are promptly available to the crew assigned to the work package.

How to implement digital twins in projects?

In an investment project, the digital twin is created long before the physical asset is built. Its creation starts during the engineering phase, and it is used and complemented during the construction phase to ensure the constructability of piping, for example. Modern digital twin platforms should have import capabilities from different systems using different standard formats, such as IFC. For preparing the handover, as-built changes should be imported back to the project’s digital twin before it is handed over to the end customer. Everything mentioned above is also applicable to brownfields and retrofits. Laser-scanned point clouds are bringing the extra layer of 3D data “as is” information to use as reference information for new design. Sophisticated conversion tools can convert point clouds into smart information-rich native models, speeding up the creation of new design and their digital twin. Thanks to intelligent interfacing, engineering data can be imported from other design applications to CADMATIC’s Digital Twin Platform.

Project data is generated, modified and stored from a number of different sources

In addition to 3D modeling tools, design applications involve a significant amount of embedded engineering practices and standards. The core of all is that project data is created and resides in the 3D CAD model. A number of calculation and analyses programs and other systems can run on top of the CAD core or beside the CAD core, incrementally enriching the digital model with additional information. The enriched digital model and the information included, can be used for several purposes during different project phases. For example one important phase, which has crucial and direct impact on delivery date, is the construction phase. Using digital information in this phase is partly already a daily routine, mainly concentrating to scheduling as one example. But when having and using digital information from different sources in your digital twin during construction phase, it may give you an extra mile and make the difference comparing to others.

Constructability is key in project success

Ensuring constructability is a core element in the successful implementation of Bonatti’s projects. It allows the company to analyze all project processes with the aim of optimizing construction sequences and practices. Interferences and possible schedule impacts are identified before starting construction, thereby preventing errors, delays or cost overruns. The effective integration of construction knowledge with planning activities, design and field operations allow Bonatti to achieve their overall project objectives in compliance with time, accuracy and HS&E requirements.

Massimiliano stresses the value of data visualization.

“When you visualize data in a realistic digital image of the plant, it dramatically improves the quality of information conveyed to the user. It gives the site management a much greater amount of information in a single screenshot than can be achieved with traditional forms of reporting such as reports, tables, and graphs. This assists the site management to take more effective operational decisions.”Read more about Bonatti case here

Collect notes from installation teams and use color-coding to visualize the installation status of the model in eShare.

What does data-driven mean?

In a data-driven project, the digital data streams are consistent, reliable and reusable across projects, project disciplines and project phases. Data drives and connects the entire process, while manual handling is minimized or eliminated to safeguard data integrity and to optimize the process. The digital twin combines the information stored in different systems, represents the single source of truth, and prevents silos of disconnected information. It will also enable handover of all released technical information to be used as a source for an operational digital twin for the Owner/Operator.

Read more about eShare and how it can serve as the platform for your digital twin.