Cut hull design time, not build quality

Overview

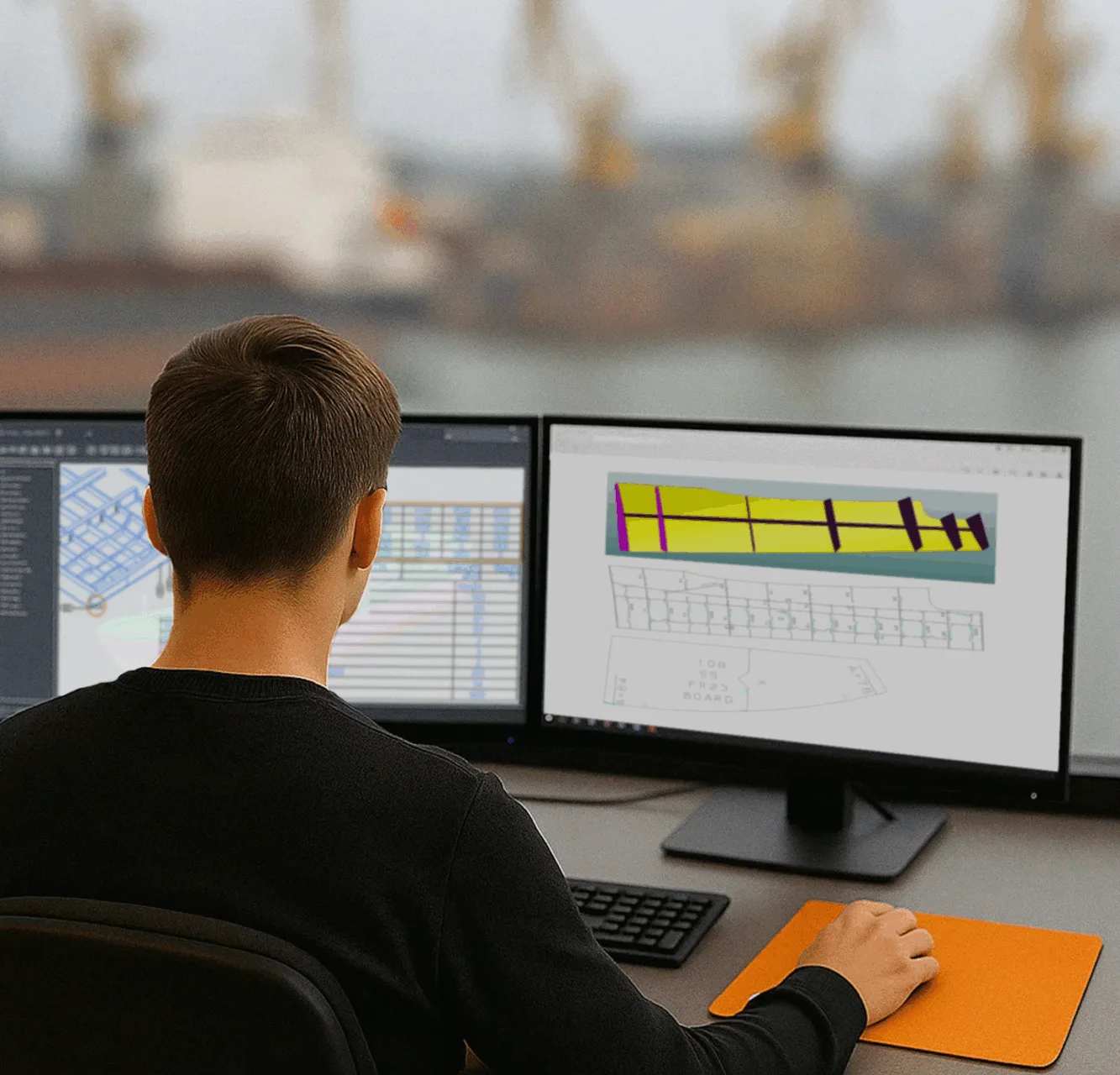

CADMATIC Hull design software brings basic and detailed design together with production-ready outputs in one intelligent 3D system. Model hull structures and shell plates with precision, automate repetitive tasks such as the extraction of production information. Cut time from design to production while improving accuracy.

- Model hull structures and shell plates with precision

- Speed up asset creation with AI-driven libraries

- Generate production-ready outputs with ease

- Improve accuracy and consistency with rule-based tools

Benefits

-

Shorten design-to-production cycles

Speed up project delivery with design reuse and automation. -

Minimize manual work and errors

Generate production data directly from the 3D model. -

Connect hull design and production teams

Enable collaboration through connected, real-time tools.

Features

-

Model it once, nail every detail

Combine flexible modeling with rule-based automation for every phase, from basic to detailed hull design.- Model in 2D or 3D: Design curved plates and internal structures, adjust parametric parts easily without remodeling.

- Rule-based design logic: Define standards and design rules up front to boost quality and keep teams aligned.

- Outfitting and Hull design software in sync: Easily share structural and equipment data, penetrations, and foundations between hull and outfitting departments.

-

Auto-generate and deliver faster

Generate ready-to-use production data from the 3D model with a few clicks.- Single-click outputs: Generate nesting data, NC files, workshop drawings, assembly plans, and other production documents directly from the model.

- Optimized processes for fabrication: Generate data for marking, cutting, bending, and welding – all optimized for real-world fabrication.

-

Review faster and collaborate smoother

Get everyone on the same page with easy model access across disciplines. Visualize, collaborate, and review all in one.- Add comments in the model: Check the model and add measurements in the viewer for direct feedback across departments and subcontractors.

- Prepare for production efficiently: Visualize production data, material use, and fabrication sequences to detect and resolve issues before construction.

Want to dive deeper? Explore supported file formats

Read more

“Creating production drawings used to be a massive job, so automated drawing creation is highly valued; the more we automate the better. It not only reduces the overall time from design to production, but we also cut out inaccuracies and inconsistencies that come with manual work.”

“This was one of the many benefits we achieved by implementing Cadmatic. We also did block drawings and production documents for steel production. It started with detail engineering for hull and machinery (piping), but within a few years we also started designing foundations, steel outfitting and electrical components.”

“For hull design, the possibility to produce approval documentation from the model is essential. Also, the library can be efficiently linked with the yard’s standards. It is crucial that we can use Cadmatic to work with different subcontractors in different offices to keep the ship model coordinated and updated for all.”

Add-ons

-

Shell plate development

Automatically unfold 3D shell plates and generate workshop-ready flat patterns and drawings.Read more -

Plate nesting

Maximize steel usage with fast, accurate nesting for shipbuilding production.Read more -

Production planning and control

Plan, track, and manage production workflows based on your 3D model.Read more -

Weld management and traceability

Monitor welds and link them to project data and documentation.Read more -

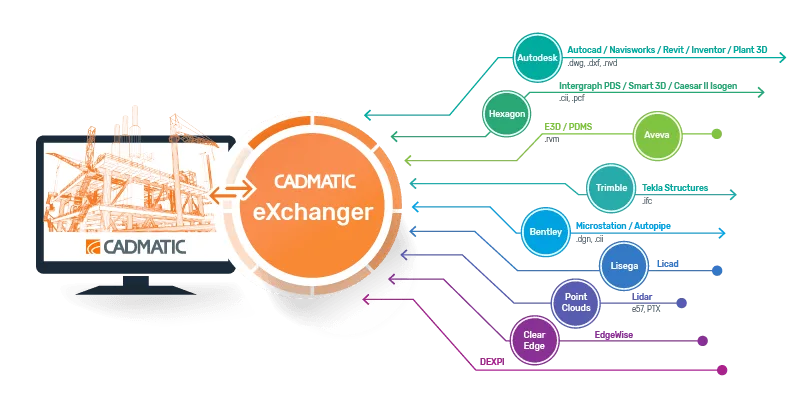

Interoperability and eXchangers

Import and export design data across software platforms.Read more

-

Shell plate development

Automatically unfold 3D shell plates and generate workshop-ready flat patterns and drawings.Read more -

Plate nesting

Maximize steel usage with fast, accurate nesting for shipbuilding production.Read more -

Production planning and control

Plan, track, and manage production workflows based on your 3D model.Read more

Frequently asked questions

Is CADMATIC Hull suitable for all ship types?

Yes. CADMATIC Hull design software is used for vessels of all sizes – from small ferries to large tankers – and supports steel and aluminum structures.

Does CADMATIC Hull have AI capabilities?

Absolutely. Cadmatic AI takes care of the repetitive work, like generating bracket type files from annotated drawings or text prompts and even updates to existing file types generated before. You get faster results and more time to focus on design.

Find more information in our documentation for AI-generated type files

Can multiple designers work on the same project?

Yes. The multi-user environment allows several designers to work on the same model simultaneously, with real-time synchronization and change tracking.