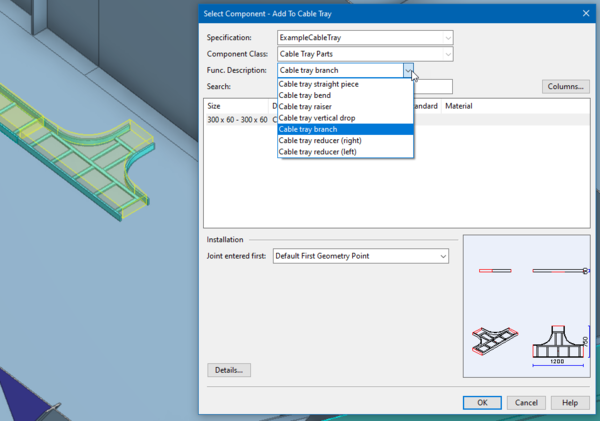

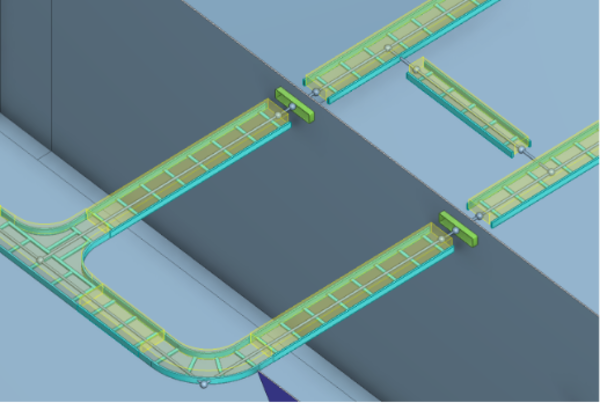

Cableways can be routed with different types of components such as trays, ladders or cable conduits. Reservation for service spaces on the components can be added. The cableway objects being placed are specification-driven. With the cable management tool, the user creates/modifies a dynamic nodal network (nodes and segments) which is automatically generated based on existing cableways and penetrations in the model. The nodal network contains so-called air jumps between cableway components based on rules.

3D Cable Design for shipbuilding

Significantly saves man-hours in cable routing and shortens the time needed for installation of pre-cut cables.

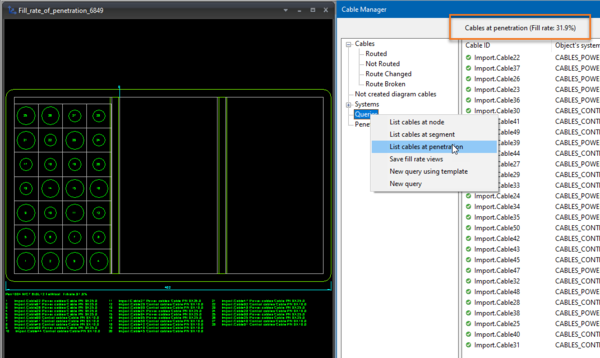

BOOK A FREE DEMOCable Router comes with a fully automated routing functionality that selects the optimized routes for cables, calculates their cut lengths and fill rates of penetrations , the allowed interference classes, segregation distances, cable stacking methods, restricted compartments or fire zones.

The system uses the nodal network to find the most optimal routes for cables between equipment and other objects and controls the status of cables. The user can easily manage which cables are routed, not routed, and for which cables the route has changed or is broken due to changes in the cable ways. Cables created in CADMATIC Electrical are fully integrated with the Cable Manager, and changes can be compared and solved. Cable definitions can be also imported easily from MS Excel via the XML link from which the Cable Management tool automatically creates cables.

Cross section views can be generated for cableways at the selected location and penetrations (including sealed penetrations, for example, Roxtec). It can be used to inspect fill rates, cable assignment in segregations on the cableway or in penetrations. Cross-section views can be attached to arrangement drawings to provide additional information for installation on site. The system automatically produces cut length lists for cable pre-cut.