TSP - Wastewater pipeline the first major MTBM project in Finland

A wastewater treatment plant in Turku, Finland, is refining their processes and preparing for climate change and disruptions with a new wastewater pipeline and UV plant. The pipeline located in the Kakolanmäki district of Turku is the first major microtunneling project in Finland that also benefits extensively from 3D modeling.

Turun seudun puhdistamo Oy (TSP) is a local wastewater treatment company in the city of Turku, Finland. They are building a pipeline of 800 meters to drain the treated wastewater to the Baltic Sea. The pipeline with an ID of 2.5 meters was jacked to 8 meters’ depth underground without having to excavate the busy streets of the district. The project kicked off in 2018, and after completion in the spring of 2023, the wastewater load is to decrease in the Turku section of the Baltic Sea. The project includes a UV disinfection plant to be built adjacent to the treatment plant, and after treatment, the wastewater will already meet the hygiene requirements set for bathing water in Finland.

“The pipeline project is proceeding on schedule, and most of the workload is done,” says Jarno Arfman, technical manager at TSP. “The connection to the sea and the outfall tunnel have been built, but the UV plant is still under construction. We are casting the concrete structures and they should be completed in the summer. We are also installing equipment, after which some of the new pipeline will be ready to use. Since the construction of our main treatment plant, this pipeline is our biggest investment, valued at 48 million euros.”

The pipeline with an ID of 2.5 meters was jacked to 8 meters’ depth without the need to excavate the streets.

Two awards recognizing innovative pipe-jacking method

The pipe-jacking phase of the project received two national awards in 2021. First it was selected as the Project of the Year by the Finnish Society for Trenchless Technology, and then it shared the second place in the annual competition of the Finnish Association of Civil Engineers RIL. The Project of the Year award promotes the use of trenchless methods and best practices and is the number-one recognition of trenchless technology in Finland. In the civil engineering competition, the project was highlighted for it use of innovative pipe jacking.

“This advanced method enabled us to install the pipeline in just five weeks,” Arfman says. “Pipe jacking saves time and energy and is therefore a more environmentally friendly installation method, even if we needed to import the pipes from outside Finland. We surveyed the costs during the planning phase and the CO2 emissions during the construction phase compared to excavation. With the pipe-jacking method, we were able to cut total emissions by circa 3,000 tCO2e compared to excavation.”

Cadmatic software is used to maintain a comprehensive 3D model of the treatment plant

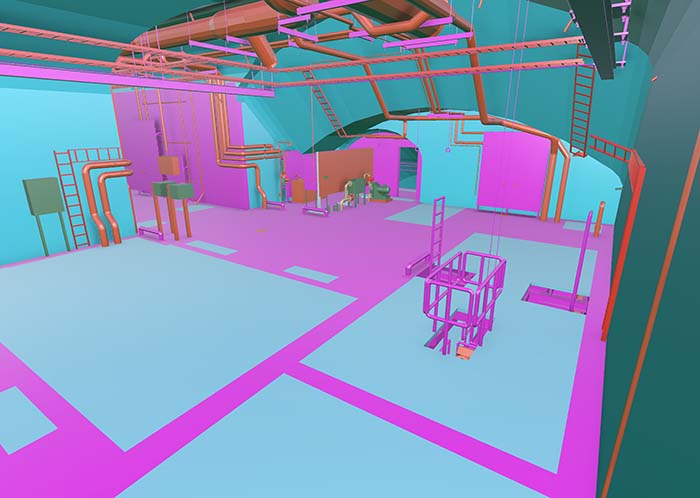

In their projects, TSP uses Cadmatic extensively to maintain an up-to-date 3D model and PI charts of its wastewater treatment plant. For this project, they implemented the eShare information management software that enables quick and easy access to design information. eShare can be integrated with other plant systems so that together with the 3D model, PI charts and other documentation, they all form the plant’s digital twin, which allows quick and easy access to all necessary data during the plant’s operation.

“Our wastewater treatment plant was originally designed using Cadmatic software, and after that we have imported rock data into the 3D model,” Arfman says. “We intend to keep on adding data to the 3D model and to increasingly utilize it in our operations. Extensive use of Cadmatic software has played an important role throughout the project from design to site management and plant operation. We used 3D models to complement drawings already during bidding, and all the design disciplines produced their parts of the project in 3D using their respective software products. We coordinated the design information without problems.”

The 3D model has at least the same information as traditional drawings. eShare has all the tools to access dimensional and material information, so printable drawings may not be needed.

Cadmatic’s design and information management applications provide efficient tools to exchange information between the various stakeholders of the project. eShare allows commenting on project details and comparing construction alternatives. It easy to print drawings from the model and to share the model to contractors, too. There is a smart link between the drawings and the 3D model. Clicking a PI chart symbol displays the item in the 3D model and vice versa.

The design of our treatment plant was originally done with Cadmatic, and rock data was also imported into the design model, Arfman says.

In addition to drawings, the contractors made use of 3D-viewing properties which may almost completely replace traditional drawings. The 3D model contains the same information as traditional drawings, or more. The viewing software includes all the tools needed to access measuring and material data, so printed drawings may not be needed at all.

“Some of our projects take place under water, but once they have been modeled, we see in the 3D model how to repair or service them. Also, our maintenance and plant operation teams use eShare. Moreover, we use various design partners, and the model is a fairly simple way to share initial information,” Arfman says.

Total service in plant model management

TSP receives total service from Cadmatic. “We receive support and service in any situation,” Arfman says. “Cadmatic’s technology enables distributing the 3D model to various engineering offices.”

The offices receive an automatically updated copy of the engineering master managed by the plant company. This way, several engineering offices can work on the model at the same time. Distribution can be arranged quickly and easily, thanks to Cadmatic’s total service.

“Our charts originally created with AutoCAD have all been transferred to be maintained and updated in CADMATIC P&ID, which was a simple process, and our overall chart, which is more complicated, will be translated before the summer,” Arfman says. “So far we haven’t tailored the software solution but have used the basic configuration. Opportunities, of course, are endless, but we want to first ensure data security, for example. Our next step may integrating the maintenance system and its documents, after which it will be possible to access maintenance and repair information directly from the model.”

This is one of the standard properties in the CADMATIC eShare system and therefore easy to implement.

More about Cadmatic solutions

Read more about eShare for EPCs and Owner/Operators.