Customer challenge

- Desire to reduce repetitive and time-consuming manual work in primary series circuit diagram generation.

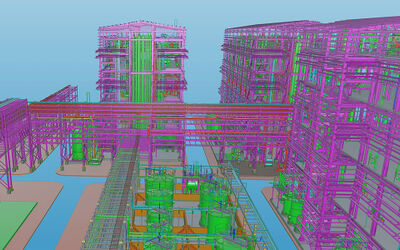

Modular generation for primary series circuit diagrams

Customer challenge

Cadmatic solution

"The use of modular generation for primary series circuit diagrams produces images that are up to 90 percent complete." – Jarmo Snellman, Project Manager

Finnish industrial turnkey supplier Makron designs and manufactures sophisticated device and production lines for tech companies. In large volume device deliveries, the design projects are large-scale too, since a single project may include over 100 engine outputs that have circuit diagrams, which as late as last year were designed at Makron by copying the basic layout for each new output again and again after making some minor amendments.

These work stages resulted in high-quality device deliveries over the years, but also in frustrated designers to some extent, and repetitive mouse arm syndrome (tenosynovitis). But now, all of this is history.

In autumn 2019, Makron and Cadmatic started discussions to eliminate this repetitive work stage. Project manager Jarmo Snellman contacted Toni Hirvonen who saw a possible solution in Cadmatic’s data management features. Cadmatic’s database features have been developed with project design data management and teamwork in mind, but the same features also enabled the creation of a prototype, which Makron tested already the same autumn.

“The prototype works very well. We proof-tested the system and when we identified issues, we could test a new version already the same day,” Jarmo Snellman says.

“We call this feature modular generation,” Toni Hirvonen adds.

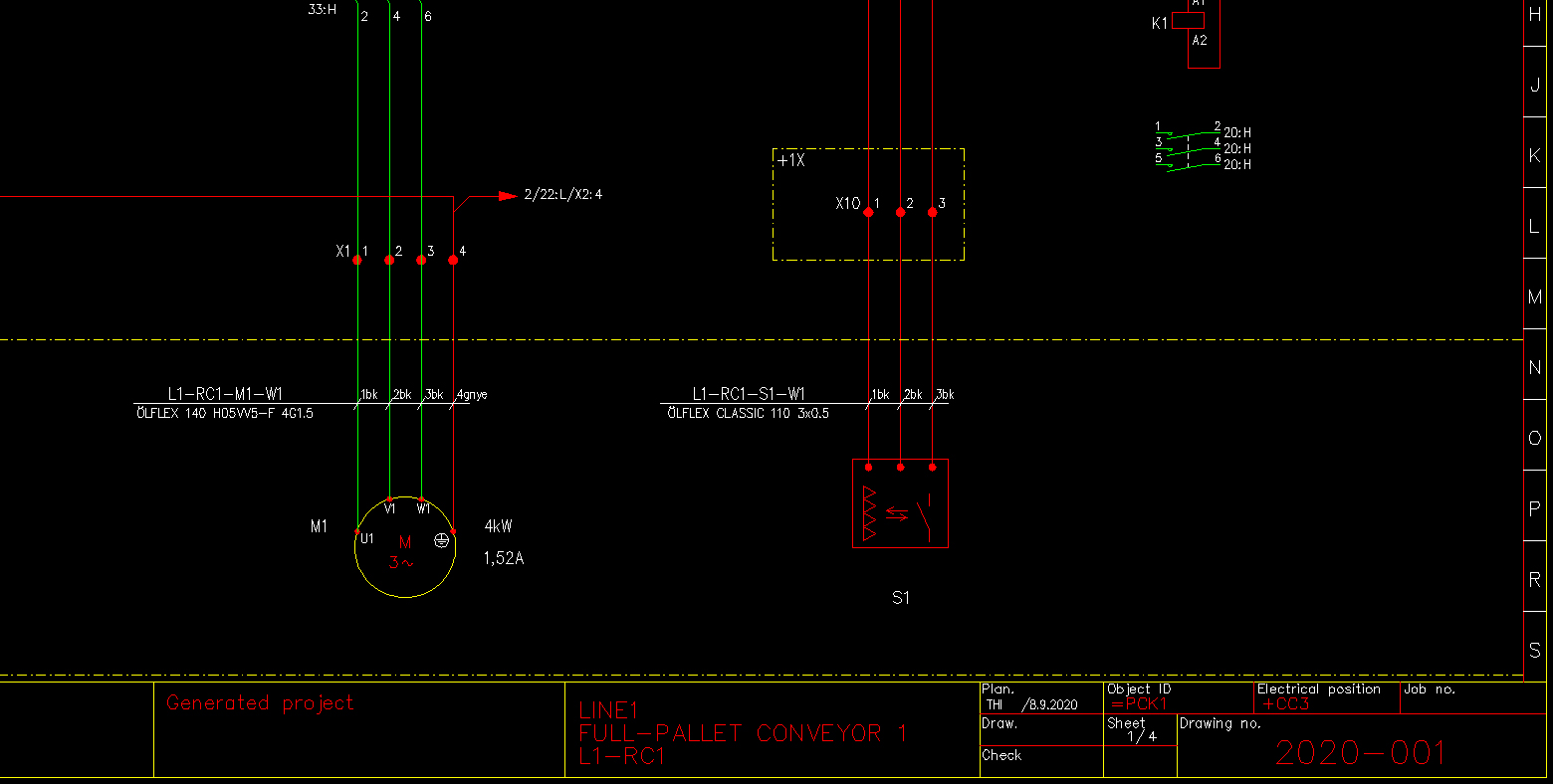

“This means database-based generation in which unique identifiers and other necessary data may be generated from MS Excel files into template modules. This enables the control of cable connections, I/O connections, device product data and plates. This kind of generation produces CAD documents with uniform quality as well as database-based MS Excel reports for the whole project”.

According to Jarmo Snellman, the use of modular generation for primary series circuit diagrams produces images that are up to 90 percent complete.

“For slightly more complex control circuit diagrams, the level of readiness is 50%, which is also remarkable. And the biggest concrete factor here is the time saving: Whereas creating diagrams for 100 engine outputs could earlier take two to three weeks, now this work can be done in half an hour. The designer can go and have a cup of coffee while the system generates the diagrams and focus on using their professional skills, such as creative thinking and finding new solutions”.

Makron’s project engineer Jarno Viikisalo is particularly happy with the standardised design achieved by modular generation.

“You won’t be able to recognize the work as being done by a particular designer, even though it may have been good work. Now we have uniform quality product, which will affect the outcome of the entire project,” Viikisalo says.

"Deadlines in machinery design are nowadays very tight and putting a machine into operation cannot wait. For this purpose, the electrical design must be started at an early stage even though some initial data is not totally clear yet. Thanks to modular generation, we are now able to delay the electrical design start-up until we have all the necessary initial data. This affects both the deadline and the quality of design,” Viikisalo explains.

"This is a remarkable advantage, and I almost wish that our competitors would not have these features at their disposal,” Jarmo Snellman sighs.

“Luckily we have a head start since we have been using modular generation since the autumn. Now it is available to all thanks to Cadmatic’s latest revision”.

Modular generation was published in CADMATIC Electrical 18.0.8 revision 1.6.2020.

If you would like to know more about how your company’s design process could be standardised, please contact Toni Hirvonen. In a one-day consultation, we will create an operation model that enables you to utilise modular generation, or we will find other means to make your design process more efficient.

Modular generation process contains the following parts:

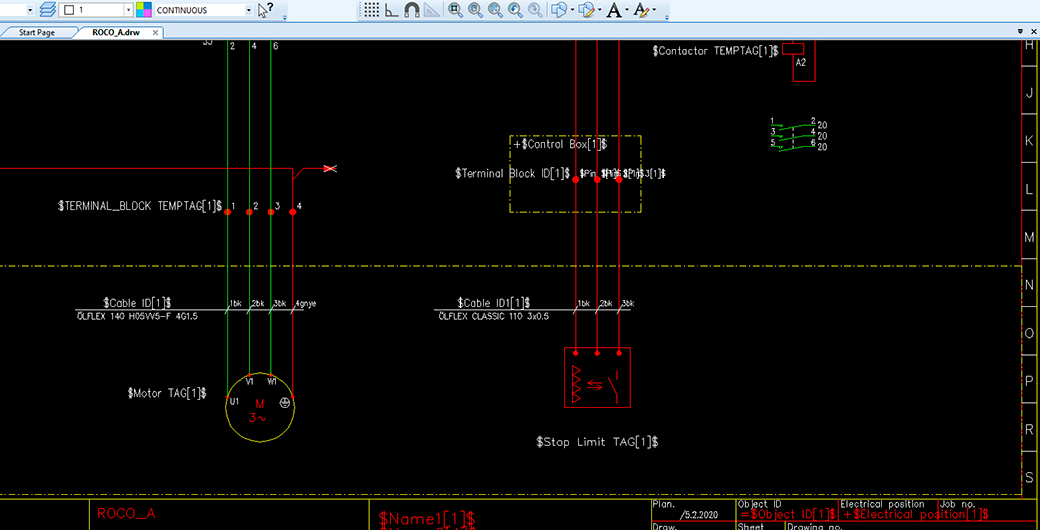

1. Modules

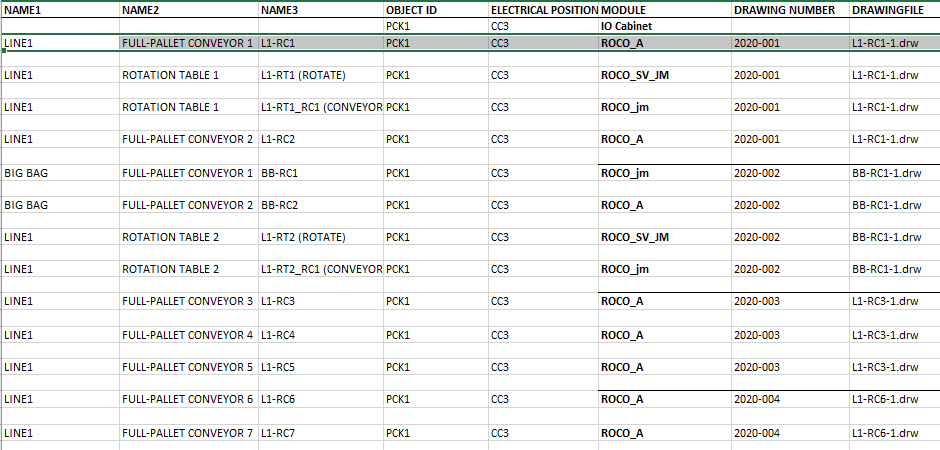

2. Excel module list

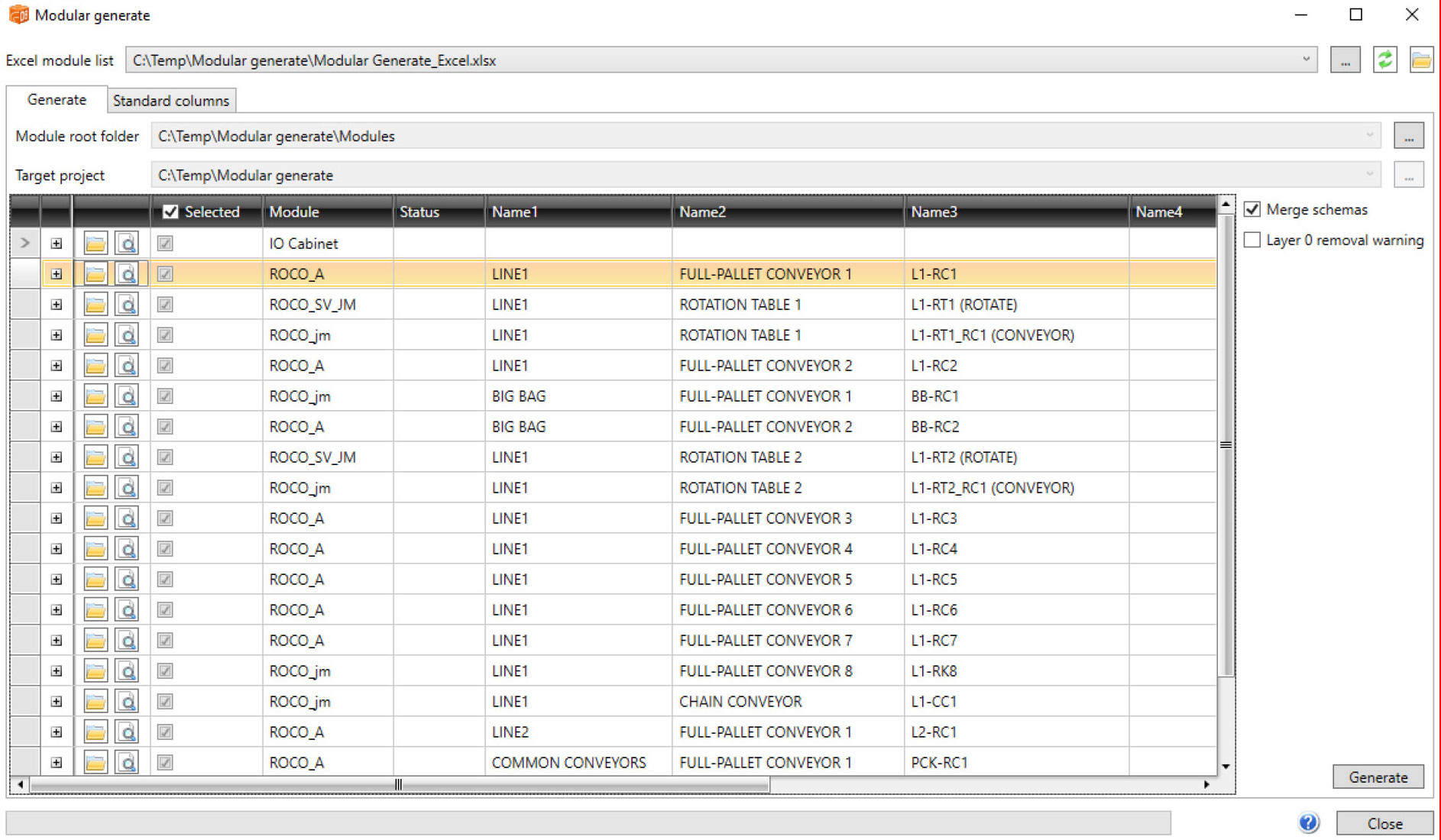

3. Modular generation function

4. Generated schemas + database information = Electrical project

Swiss precision engineering

One plant every 60 days!