Production control and planning using machine learning

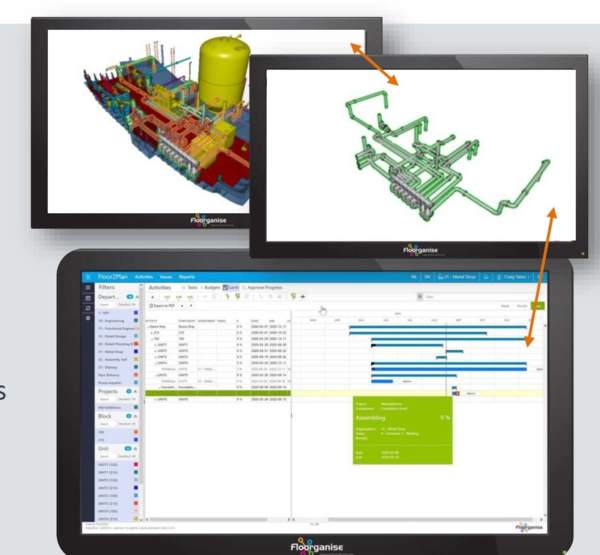

CADMATIC Floorganise enhances ship (project) planning and control processes as a Ship Production Execution System (MES) through automation and integration of engineering data, the 3D model and available IT systems (e.g. ERP, time & attendance, project planning software).

Planning, production and engineering departments and even the supply chain can work on the same model and create deeper more predictable and detailed plans on the actual 3D model in parallel. This allows for a process that follows the optimized building strategy based on the particulars of both the project as well as the yard. Processes rely on up-to-date integrated and factual data, thereby vastly reducing failure costs.

Create task-level planning based on the work breakdown and BOM from the actual engineering model refined with KPI’s, resources and business logic derived from your own yard. Create kits and work packages, visualize progress status and project risks in 3D but also retrieve daily updates on technical progress and hours worked per individual worker through dedicated modules. All synchronized with your current IT landscape where applicable.